- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

feature

Bottom brackets March 2021

Bottom brackets March 2021Bottom brackets - get the insider info on your bike's beefiest bearing

Bottom brackets should be seen and not heard. Unfortunately, that’s not always the case, and a simple component used to attach the cranks to the frame can cause issues. And when it comes time to replace a worn bottom bracket, it can be mystifying trying to get the correct replacement.

Compatibility issues

In an ideal world, there would be one single bottom bracket standard, but in a sport that has seen vast technological advances, the bottom bracket has been dragged, sometimes kicking and screaming, into the modern world with the result being a veritable minefield of choice.

In this guide we’ll run you through all the main bottom bracket types to help you identify the one on your bike when you need to replace it, and what you need to know about each system. Thankfully, it’s gotten a lot easier to find replacement bearings and while there have been some ruinous designs, some parts of the industry are moving towards more sensible solutions that provide better reliability and easier serviceability. There are also lots of bottom bracket conversion kits that let you fit cranks from one standard to a frame with another standard.

To thread or press, that is the question

There are two main types of bottom bracket design, one with a threaded shell which the bearings screw into, or a press-fit design which the bearings press into the shell. Bottom brackets are largely distinguished by the shell and axle width and the diameter of the shell and axle.

Threaded

Bearings that thread into the bottom bracket shell are the most common. It does mean the frame needs to be made from metal, or for a carbon frame to have bonded metal inserts to carry the necessary threads.

BSA, or English threaded bottom bracket, is the most common threaded standard in use today. It uses a 68mm wide shell for road bikes, 73mm on mountain bikes, with a 34.8mm diameter shell. A few bike brands use an Italian threaded bottom bracket but these are rare.

In the olden days, a bicycle would have a cottered bottom bracket, but they are all but obsolete these days. They were replaced by square taper design, using a 17mm axle with a square tapered ned that fit into square holes in the crank. It’s still used on some cheaper bikes but largely redundant on modern road bikes.

Splined bottom brackets were popular for a while, with the likes of Shimano’s Octalink popular for several years. It used a spindle with eight splines and was seen on road and mountain bikes. ISIS Drive was another design similar to Shimano’s patented design.

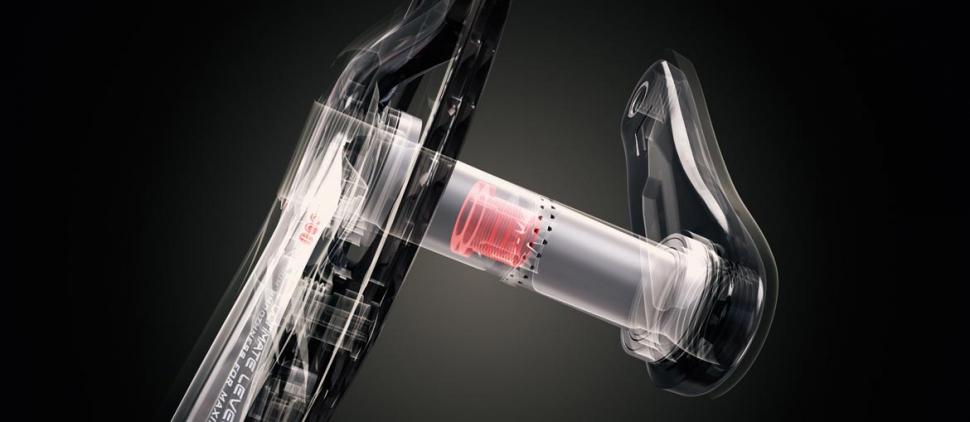

Hollowtech II

A threaded bottom bracket with outboard bearings is probably the most common design in use today. Placing the bearings external to the frame allowed for a larger axle for more stiffness, and hollowing it out saved weight. The bearings being further apart also contributed to the stiffness benefits.

Shimano developed Hollowtech in 2003 and changed the bottom bracket world forever. It moved the bearings outside of the frame whilst still screwing into the frame. This allowed larger bearings and axles for stiffness and weight benefits.

It uses a 24mm diameter axle with a 68mm wide shell for road bikes, and 73mm wide shell for mountain bikes. English threading has a left-hand thread on the drive side and right-hand thread on the non-drive side.

Many companies still use in face of the press-fit rise and some brands are even ditching press-fit and going back to it. There are now many conversion kits that let you fit a raft of other crank standards, including 30mm axles, to Hollowtech bottom brackets, increasing its popularity.

MegaExo, X-Type and GXP

There exist similar designs to Shimano’s Hollowtech, following the same principle of outboard bearings inside a regular threaded shell and a 24mm axle.

Truvativ, now owned by SRAM, developed Giga X Pipe, GXP for short, was an evolution of ISIS. It used a right side bearing floating on the crank and a left side bearing sitting flush with the stepped axle design.

FSA developed MegaExo, also using a 24mm axle with a 68mm shell and 73mm for mountain bikes.

X-Type was developed by RaceFace and also used a 24mm axle with outboard bearings.

Campagnolo Ultra-Torque and Power Torque

Campagnolo developed an interesting design called Ultra Torque which was its answer to Shimano’s Hollowtech II in 2006.

The 25mm diameter crank axle was split in half and joined with a Hirth joint and large diameter bolt. The bearings sat outboard of the frame.

It was joined by Power Torque in 2011 which used a single piece axle fixed to the right crank and used outboard bearings.

Campagnolo provides bearings to fit both cranks to most bottom brackets including threaded and press-fit.

Press-fit

With the advent of carbon fibre and the development of lightweight and stiff race frames, came the advent of the press-fit bottom bracket. Carbon is a wonderful material, but it has its limits, namely, you can’t cut threads into it for a threaded bottom bracket, and bonding aluminium sleeves is troublesome.

The solution was to press bearings directly into the frame. The benefits included more design freedom and stiffness and weight advantages over threaded designs. There now exist numerous flavours of press-fit bottom bracket, but most are not compatible with other designs, though in some cases conversion kits are available.

Cannondale BB30

Cannondale, with the invention of BB30 in 2000, came up with a solution. BB30 saw the bearings being pressed directly into a huge 42m diameter carbon shell and a larger, 30mm diameter bottom bracket spindle made from aluminium. It offered more stiffness and less weight.

Cannondale evolved it with BB30A. It uses an asymmetrical shell that is 5mm wider on the non-drive side to create a wider, stiffer base. The non-drive side crankarm angle is changed to maintain the same Q factor and even out ankle clearance on both sides

In 2015 Cannondale developed it further, introducing PF30A which moved away from bearings held in place by clips to press-fit bearings in plastic cups that pushed straight into the carbon bottom bracket shell. This change also required a bigger bottom bracket shell, so it grew from 42 to 46mm.

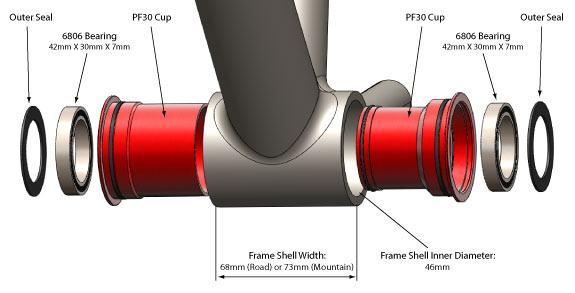

PF30

BB30 required extremely precise machined aluminium bottom bracket shells with strict tolerances to contain the bearings and clips. SRAM press-fit 30 and launched it to the world in 2009.

The shell size few from 42 to 46mm to accommodate the plastic cups containing the bearings. It uses the same 30mm axle as BB30 and 68mm width for road bikes and 73mm for mountain bikes.

It made it possible for frame designers to create carbon fibre frames with oversize bottom brackets for stiffness and weight benefits. It didn't require as strict tolerances compared to Cannondale's BB30 design.

This has led to many of the issues associated with press-fit bottom brackets because you're hoping the fit between the plastic cup and carbon shell is good enough to prevent any unwanted movement which can lead to creaking.

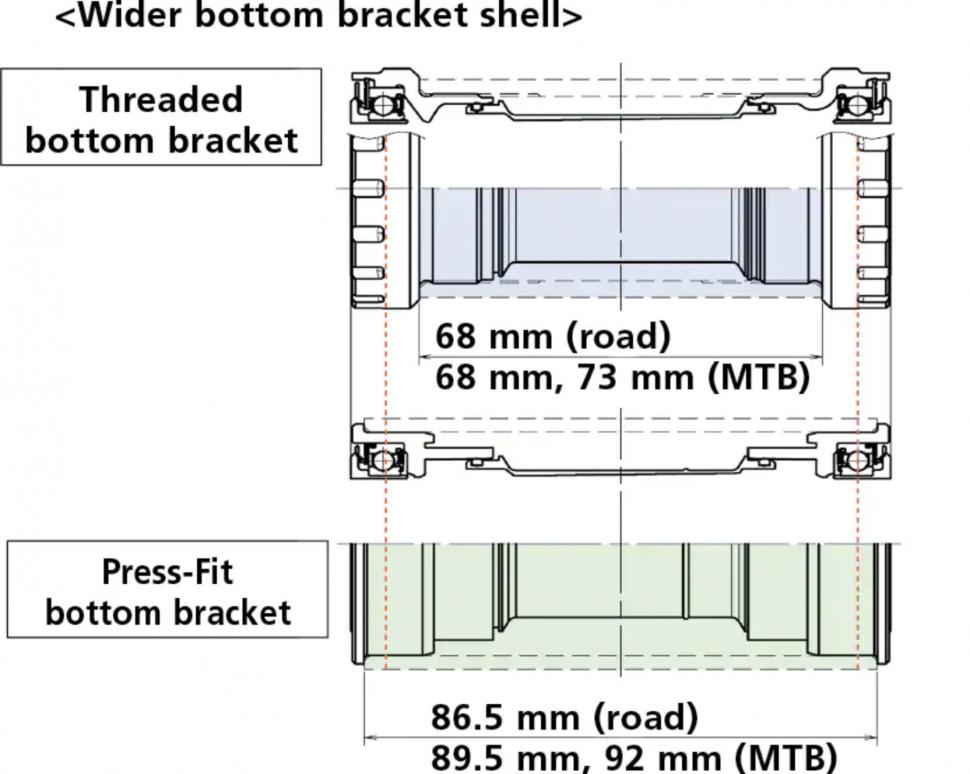

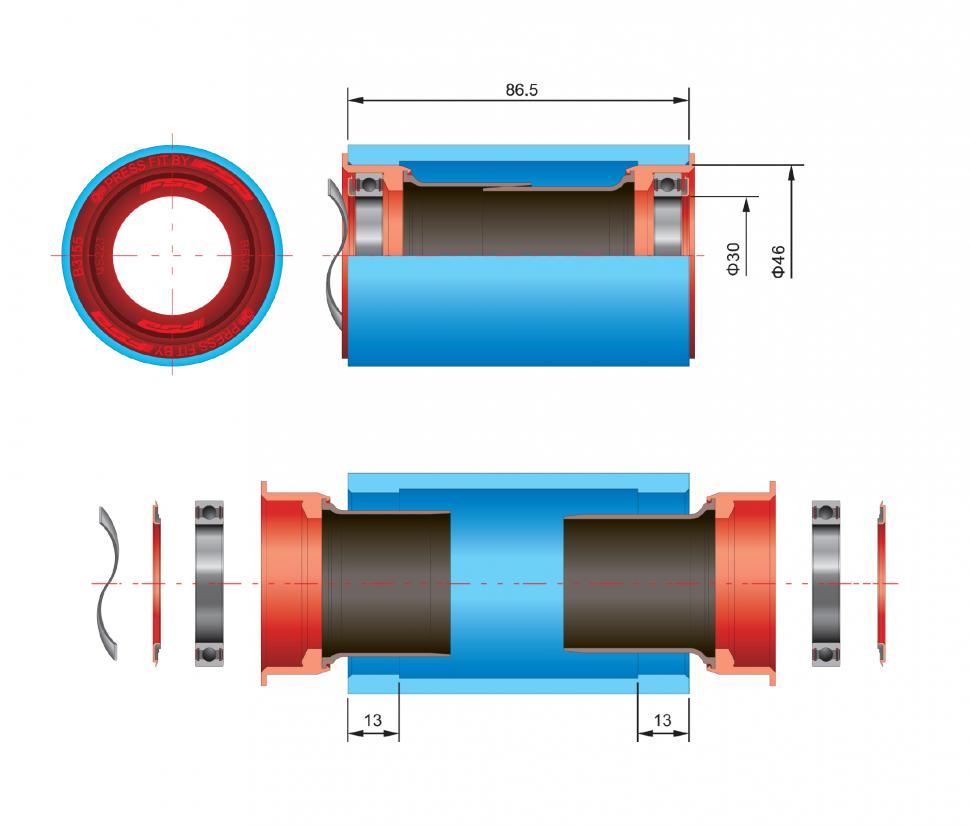

Shimano BB86

Shimano developed its press-fit standard using 41mm diameter bearing cups with an 86.5mm wide bottom bracket shell for the road, and 89.5 or 92mm for mountain bike. It’s designed to be used with a 24mm axle, Shimano long shunning the temptation to use a 30mm axle like its major rivals.

It’s sometimes referred to as PF41 because of the 41mm shell diameter.

Trek BB90 and BB95

Trek developed its bottom bracket for its road and mountains bikes. The bearings pressed directly into the frame with a 90.5mm wide shell on road bikes, and 95.5mm wide shell on mountain bikes, with a 37mm shell diameter.

It’s arguably one of the most troublesome systems in current use if internet forums are anything to go by. No wonder Trek has adopted T47 on its new 2020 Domane road bike.

BB386 EVO

This is a standard introduced by FSA in 2011 that aimed to solve some of the issues with compatibility, designed as it was work with most current bottom bracket standards. It’s an open standard and quite a few manufacturers have been adopting it.

It uses an 86.5mm wide shell, to position the bearings further apart for more stiffness, with a 30mm axle that is as long as that of an external system. It’s also compatible with threaded bottom bracket shells.

You can get a BB386EVO bottom bracket that’ll fit a threaded 68mm BB shell, so you can use new standard cranks on an old standard frame.

ThreadFit82.5

When Colnago wanted to create a bottom bracket for its then-new C60 in 2015, it designed to come up with its design that aimed to address the issues of press-fit but retain the key advantages. It uses screw-in alloy cups to house the bottom bracket bearings. The cups are replaceable so there’s no risk of damaging the frame. It’s compatible with BB86 and BB386EVO.

T47

T47 was developed by Chris King back in 2015 and uses an oversized and threaded design. It has the same diameter shell as a pressfit30 bottom bracket, but with the threaded cups of a traditional BSA-threaded bottom bracket. It’s an open standard so any frame manufacturer can use it.

It hasn’t been that widely adopted, just a few niche bike brands to begin with, but it’s gaining momentum with the likes of Trek using it on their new 2020 Domane endurance bike.

Trek has hacked the standard slightly; they’ve made the BB shell 1mm narrower so it can add 0.5mm of extra material to the tool flanges to make it easier to remove them. It’s compatible with all off-the-shelf T47 internal BBs, though.

Cervelo BBRight

Cervelo developed BBRight for its road frames using an 11mm wider shell jus ton the non-drive side with bearings pressed directly into the frame. That produced a 79mm wide shell with a 42mm diameter.

Specialized OSBB

Specialized developed OSBB (oversize bottom bracket) in two slight variations for alloy and carbon frames. The latter uses a 46mm diameter shell with a 61mm width to work with its Fact cranks, using removable cups.

It's similar to BB30 and PF30 with a 30mm spindle but the shell is narrower to decrease the Q-Factor. In 2015 it moved OSBB to BB30 and in recent years it has started going back to threaded bottom brackets, with OSBB only found on its high-end models.

SRAM DUB

Introduced in 2018 primarily for mountain bikes but coming to the road market is a new system that SRAM hopes will be compatible with all current bottom brackets and frame designs, and make choosing a bottom bracket easier.

Durable Unifying Bottom Bracket, or DUB for short, uses a 28.99mm (very precise!) axle diameter replacing the company’s previous GXP and BB30 bottom brackets and claims it is lighter than BB30. It has also worked on the sealing to ensure good longevity.

Installation

There are key differences when installing a threaded versus press-fit bottom bracket.

Most people are cool with unscrewing something, but taking a mallet/drift to an expensive bike is a whole other thing.

Installing a threaded bottom bracket is relatively easy. You need the correct tool and some grease, and provided you follow the instructions carefully it’s plain sailing.

- How to fit a threaded bottom bracket

In some cases you might need to face the frame, removing excess paint/material to ensure the bearing sits flush against the frame. Most good frames should be done at the factory but that’s not always the case, so you might need to visit your bike shop in rare cases.

Removing a threaded bottom bracket, provided you remembered to grease the threads, is as easy as installing it.

Installing a press-fit bottom bracket requires its own special tool which is an expensive investment for most home mechanics. The tool basically squashes the bearings into the frame from either side, and in most cases, it’s a relatively easy task, depending on the tolerances of the frame and bearing cups.

- How to remove press-fit bottom bracket bearings

Removing a press-fit bottom bracket requires another specific tool and a whole load of trust. It’s essentially a case of using a mallet/hammer to whack the bearings out using the special tool seated against the inside of the bearing cups.

Take it from me, squaring up a hammer at a small tool placed inside the bottom bracket of your £2,500 700g frame is a heart in mount moment.

Pressing issues

Press-fit bottom brackets have become hugely popular, and seemingly every bike brand has come up with their variation on the theme, causing headaches for consumers trying to source replacement bearings. Installation and removal also require special tools and perfect tolerances between the frame and bearing to prevent issues arising. The creaking press-fit bottom bracket is a regular complaint among cyclists.

Is press-fit dead? road.cc investigates and speaks to Specialized and Bowman Cycles

What's your bottom bracket of choice? What have your experiences be with different bottom brackets over the years? Let's hear your stories below.

David worked on the road.cc tech team from 2012-2020. Previously he was editor of Bikemagic.com and before that staff writer at RCUK. He's a seasoned cyclist of all disciplines, from road to mountain biking, touring to cyclo-cross, he only wishes he had time to ride them all. He's mildly competitive, though he'll never admit it, and is a frequent road racer but is too lazy to do really well. He currently resides in the Cotswolds, and you can now find him over on his own YouTube channel David Arthur - Just Ride Bikes.

Latest Comments

- Romanp 1 sec ago

I figured out a reason of that squeaking noise. I have xpresso 2 and 7, and also xpro 10 pedals, and that squeaking isn't present only at Xpresso 2...

- Dunnoeither 14 min 49 sec ago

There’s one other big reason we’re not going to fly to launches from now on: the world IS in the middle of a man-made climate emergency so taking...

- ktache 24 min 6 sec ago

Surely some nice bright colours, some stripes, it is the seaside. Like beach huts...

- Jimnm 57 min 54 sec ago

Perhaps they need to reduce prices dramatically and try to rely on turnover to make a profit. Bikes are more expensive than some motor vehicles...

- MichaelWinnerRIP 1 hour 1 min ago

Italian tourist and pussycat in Portugal.

- Backladder 1 hour 16 min ago

Am I the only one who thinks the brake levers look awful too?

- David9694 1 hour 48 min ago

Yep, it's official - reds under the, er, bonnet...

- Rendel Harris 2 hours 27 min ago

Indeed, I was drawing from personal experience – I don't use it that often but it's such a nice bit of infrastructure that I sometimes go out of my...

- paulgardener@gmail.com 2 hours 31 min ago

Except socialism doesn't work like that in real life. It's the capitals countries that try to look after those in need, and the average person's...

- KDee 3 hours 29 min ago

It's the mass that's the issue. Two people on a petrol powered scooter can really mess up a cyclist. Also the fact so many of the petrol scooters...

Add new comment

17 comments

I feel like there is not enough choice in the market. There needs to be at least two more 'standards' for bottom brackets. I'm sure the industry will address this soon.

https://xkcd.com/927/

There's nothing wrong with press fit as a concept. Theoretically it should be more suited to carbon frames than threaded. IF (and it's a big IF), manufacturers could build frames consistently to the right tolderances, press fit should work fine, without creaking. Who are the best/worst at this?

I disagree. I don't think hammers should be involved in the removal of any components. Carbon fibre is also not particularly reistant to abrasion so forcing interference fit components into a carbon fibre orifice does not seem like the ideal solution.

Fit the BB and find it is a bit creaky, maybe some loctite should have been used to hold it firmly in place. Bearing has to be hammered out to start again instead of unscrewed. Is this bearing now still suitable for use or has it been damaged?

Heresy! Burn the witch!

I will never buy another bike with a pressfit bottom bracket, they are the ejaculate of Satan.

Fortunately the bike industry looks like it is starting to turn its back on what is an embarrassment to bicycle engineering.

The biggest bearing on most bikes is in the headset

"a heart in mount moment"

A Freudian slip?

Thank you for such an in-depth article - even if the lesson I take from it is mostly "let the bike shop deal with this", it's good to be aware of what the issues are and options at replacement time. So such a level of detail is very much appreciated.

The lesson for me is stick to threaded BBs!

agree.

Even in the square taper BB era there was the issue with JIS/ISO standards but yeah, I also long for those simpler times instead of the current jungle. I still have a square taper bb on one of my bikes and the only drawback there is weight.

My other bike has PF30, so far so good but it better keep because I don't intend to make Park Tool even richer and my toolbox is full as it is. When I purchase a new bike, the BB standard will be an element in the decision, I want something threaded (you hear that, Open Cycles...).

But 'rich' Park Tools do invest some of their profits into excellent bike maintenance tutorials (you hear that, Xenophon2…).

Two of my three bikes have a Campagnolo Record square taper BB with matching crankset from 2006/7 they have done squillions of miles and still spin like new. In fact the Record groupset from 2006 is a lovely set of equipment. I have a few spares in my garage for the future.

Not fashionable these days.

Yup. Been there with Hollowtech II. After getting really fed up of near annual bearing replacement I reverted to UN55 square taper BB. The one on my hack bike used throughout the winter remains sweet after 15 years.

Which goes to show that, in cycling as in all things, you need a little luck. I've had very different experiences from yours. The only square taper BB I've owned needed new bearings every twenty minutes, whereas all my Hollowtech II stuff, and Campag Ultra/Power Torque too, have behaved impeccably, going years between re-greasings.

Of course, it could be down to the almost complete absence of torque produced by my legs?

Been there with Hollowtech II

This just shows how experiences differ. I always used to have difficulties with square taper and the adjustment to stop the big ring grating against the cage. My 2001 Merlin was no different, but when I belatedly heard about Hollowtech around 2009 I installed one straight away and have had no trouble or bearing replacements since.