- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

feature

3D printed cycling tech — what 3D printed bike products have taken off, and what's coming in the future?

The world has gone 3D printing mad, and it seems like there is literally nothing that can’t be made using additive manufacture. That has extended to bikes too, of course, with everything thing from components, to contact points to whole bike frames being 3D printed nowadays.

If 3D printing in the bike industry is still all a bit new to you, we've compiled this handy guide to just about every genre of bike thing we can think of that has been 3D printed to date, and some that are yet to be made but we can expect in the near future...

Saddles

One of the first areas that 3D printing made itself known to the cycling industry was the saddle, and there’s now a huge array to choose from. Specialized was one of the first on the scene, calling its intricate elastomeric lattice structure 'Mirror' tech.

The concept of using 3D printing for saddles is largely similar across brands, with Selle San Marco, Fizik, Selle Italia and Specialized featuring such saddles in their lineups. These brands claim that they’re able to print saddle padding that is comfortable, supportive and incredibly resilient, which overcomes the shortfalls of traditional foam.

> Staff bikes: Jamie's 2022 Specialized Allez Sprint dream build

I’ve been using a 3D printed saddle for some time now, and am suitably impressed with their durability. The benefits of being able to tailor the density of certain sections of the saddle are also clear; however, the downside is nearly always the price. 3D printing is best suited to small-volume production, so we tend to see 3D printed saddles towards the top of the price range.

Currently in for review, we have plenty more 3D printed saddles. The Bjorn Setka (shown above) is reportedly the lightest saddle with a 3D printed pad, and the Posedla Joyseat is a 3D printed saddle that has been tailored to my exact ass shape! Is this the future of saddles?

Handlebars, stems and cockpits

Moving to the front of the bike, and we’ve seen plenty of 3D printed bars and stems both in the World Tour and on the track.

It could be argued that 3D printing has had a rocky start here, after the Australian pursuit team quite literally came crashing down at the 2020 Tokyo Olympics. The 3D printed titanium base bar by Bastion Cycles failed during the start of the event, with reports stating that it was caused by inadequate design specifications supplied to the manufacturer, and a failure to conduct adequate fatigue testing in the lead-up to use in competition.

Since then, 3D printed bars and stems have seen far more success though. Many of the pros can be seen riding custom TT extensions in time trials, and last year we even got our hands on a 3D printed stem of our own.

The Mythos Elix stem (below) claims to be the world’s first commercially available 3D printed stem, and a look into what is possible in the future. At £500 it doesn’t make a whole lot of commercial sense right now but even so, we found that it performed well, albeit no better than a good conventionally manufactured stem.

Whereas many 3D printed cycling components are made of titanium, The Elix stem is made of a material called Scalmalloy, an alloy made of aluminium, magnesium and scandium. The first aluminium-scandium alloys were in fact developed by Russia during the Cold War for use in MiG aircraft.

There was a bit of a vogue for it among bike builders in the early 2000s, and some makers have stuck with the material. Scalmalloy was developed by Airbus and contains zirconium and manganese as well as aluminium, magnesium, and scandium. It’s widely considered the strongest aluminium alloy that’s suitable for additive manufacture. Quite a good thing to make a stem out of, then!

The fastest bike in the world?

Now most of us couldn’t even justify a stem made of Scalmalloy... but what if you were after a whole bike? Well, that’s exactly what Filippo Ganna got. This Pinarello Bolide F HR 3D claims to be the world’s first and fastest high performance 3D printed bike ever built. It’s hard to argue with that, as Ganna destroyed the Hour Record last year on this very bike.

The concept behind the F HR 3D is to blend strength and stiffness with aero gains, relying on a production method that would allow for millimetre-perfect sizing. From the seat tube that imitates a humpback whale to the 3D printed titanium one-piece bar and stem, this really is a special bike that will surely go down in history.

When asked about the bike, Pinarello said: “3D printing allowed us to introduce new shapes and features that are impossible to replicate with existing carbon fibre techniques.

"With this new method, we have created a unique aerodynamic shape and reached an incredible level of stiffness.

"Moreover, [3D printing] made it possible to add internal reinforcement, and create a totally new shape of head tube and importantly, it also drastically cuts development time because we were no longer held back by the traditional time constraints of mould production for a carbon fibre frame.”

It appears, then, that it is use cases like these that 3D printing really shines.

A Moot(s) point?

Bikes like the Pinarello above are lovely to look at, but even with a briefcase full of money you still couldn’t get your hands on one. So, when are we likely to see 3D printed bikes available to buy? Well, the truth is that the transition is already happening right in front of our very eyes. Moots, the American titanium bike specialists, are already using 3D printed dropouts on selected frames.

I recently got the chance to see these printed lugs before they made their way into a frame, and the obvious question was "why?"

Moots explained that weight saving and controlled stiffness were definitely factors, but also raised the interesting point of wastage. The size of a piece of 6/4 billet to make a part of similar dimensions to the printed part you see would weigh 2.4 lbs, per side, not to mention the hours of machine time and the limitations in design features.

This creates about 85% of waste. The way a 3D printer works is to put down a very thin layer, 60 microns thick in this case, in an Argon-filled chamber, and then a laser fuses the material along a precise computer-controlled pattern. The waste for this process is less than 10%.

That’s a significant saving then! Especially when dealing with materials as expensive as titanium.

More frames

A little further digging into those Moots frames would indicate that its partners Mirada Pro went one step further before going bust in 2017. Check out this rather mental-looking frame!

Or how about the Superstrata bike and e-bike?

This is 3D printed from continuous carbon fibre and is available to purchase now... although, we'd strongly recommend checking comments under the record-breaking crowdfunder and recent reviews first...

Additive manufacturing often seems to take this unique almost organic style where the standard rulebook and limitations of conventional manufacturing techniques are chucked out the window. The bike prototype shown above, that we first reported on in 2015, was one of the more promising designs we'd seen at the time but even the inventor, an industrial designer, admitted it was a long way from being fully rideable.

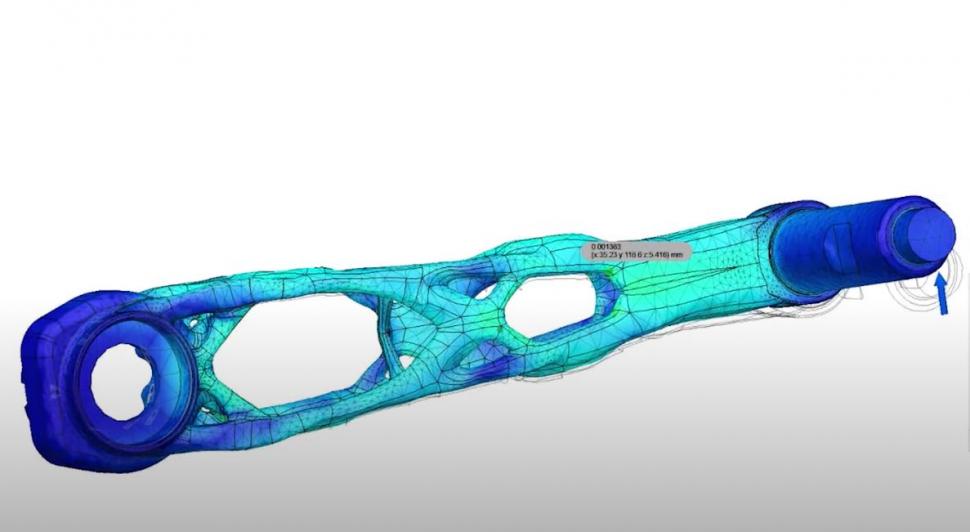

SRAM prototype cranks

Just take these SRAM cranks as an example. They certainly split opinions when we wrote about them in 2021.

Whether you like them or not, these prototype cranks are said to be twice as strong as ones developed and manufactured using traditional techniques, and 20% lighter. However, as we haven’t yet seen them used even on a pro's bike yet, we’re assuming that they’re either wildly expensive, SRAM has run into some problems with them, or both...

SRAM has used a program called Fusion 360 to develop the cranks. They’re designed by a computer and input data, such as forces.

Silca 3D print A LOT

If you’re looking for 3D printed tech that you can actually buy, then really there’s only one place to look, and that’s Silca. Silca has spent the last few years 3D printing just about everything from out in-front computer mounts, to tools and pressure gauges.

We're sure Silca's CEO Josh Poertner has plenty more ideas up his sleeve of what to 3D print next!

3D printed tech that you can eat

A 3D printed hammer is pretty out there, but how about these? Oh yes, even your vitamins can now be 3D printed. Nourished is a company that creates 3D-printed gummies which are customised to your individual health requirements.

We’ve already seen many examples of how additive manufacturing has been used to create personalised parts and components, but Nourished believes that if anything in the world should be personalised, it should be our health and wellness.

The future (According to Canyon?)

Speaking of personalised, Canyon seems to be gearing up to release some custom tech of its own by partnering with TheMagic5, the world’s first company to offer custom-fit swimming goggles using smartphone facial scanning technology. The only issue is we have no idea what components it will be, s let us know your best guess in the comments section below!

The press release simply stated that the aim of the new partnership between TheMagic5 and Canyon is to "find the next level of technology-based custom-fit products by expanding the application of their [TheMagic5's] proprietary fitting technology."

That doesn’t give a lot away... could it be saddles? You’re going to have to remember to delete the pictures of your ass off the phone if it is! Or maybe hoods, or aero bars. Either way, we’re excited to see what the future holds.

3D printing is already changing cycling for the better

Of course, there are plenty of applications for 3D printing that we now take for granted, despite it still being a technology that is in its infancy. Remember a few years ago when getting GoPro and light mounts was a right PITA? Well that problem has been all but fixed by companies such as Raceware, who now make just about every mount possible.

It doesn’t matter that you’re one of only about three people on the planet riding a Trek Madone with a Deda stem and want to run a Bryton cycle computer with a Varia light and camera, because 3D printing costs the same per unit to produce three as it dpes three million.

Because you don’t need to make injection moulds you can just run off a few, which is great whether you’re rapid prototyping a new design or making something for an extremely limited market.

> Staff Bikes: Jamie's Custom Specialized Allez Sprint

I even 3D printed my very own headset cap (above), not because I needed to, just because I thought it might look a bit better than the original.

3D Printing is here to stay

So where are we heading next? Well, one thing for sure is that 3D printing is likely only going to get more prominent in the world of cycling. Not just for rapid prototyping (Like on this Mason fork above) but for both plastic and metal end products too.

Pinarello told us: “The next step will be to make it more affordable by finding ways to scan riders with more affordable equipment and automatically design each unique bike – from a world champion to every World Tour rider, and eventually to each and every cyclist out there.”

Which component would you most like to get 3D printed? Let us know in the comments section below, but if it’s your favourite route, a helmet or a model of Tom Dumoulin then I’m afraid it’s already been done!

Jamie has been riding bikes since a tender age but really caught the bug for racing and reviewing whilst studying towards a master's in Mechanical engineering at Swansea University. Having graduated, he decided he really quite liked working with bikes and is now a full-time addition to the road.cc team. When not writing about tech news or working on the Youtube channel, you can still find him racing local crits trying to cling on to his cat 2 licence...and missing every break going...

Latest Comments

- Bungle_52 3 hours 25 min ago

In case anyone missed it in yesterdays blog here are the two pevious articles. The second one contains the testimony from the driver....

- bensynnock 3 hours 29 min ago

My understanding is that you have to sue for some crazy amount or you won't be taken seriously.

- David9694 3 hours 33 min ago

The old role was appointed at the Mayor's pleasure; is in addition to the permanent staff of the Combined Authority. I'm not sure if Adam was an...

- chrisonabike 3 hours 38 min ago

Ah... but which civilisation? If arguing from precedent (or even "moral ground") - with the benefit of almost no political, historical knowledge...

- WillPage 4 hours 59 min ago

Nothing says "welcoming environment" like uniformed thugs, umm I mean "security patrols " roaming the area.

- galibiervelo 6 hours 17 min ago

That is class news. Super bikes and vision. Bet there will be no stand at the Taiwan bike show next year! Big luck to all the team

- Destroyer666 6 hours 59 min ago

Pretty clearly stated several times in the text that the issue was not related just to his son. And besides, everybody watching the races could see...

- Rendel Harris 7 hours 15 min ago

All Fizik and Selle Italia saddles (though not all their other products) are made in Italy I believe, and their 3D printed models definitely are.

- chrisonabike 7 hours 41 min ago

If you're not on the road with a car, I bet its driver is much less likely to swerve into your space *. Because you're not "in the way"! (Any...

- mdavidford 7 hours 57 min ago

The problem with this argument, though, is that it's just not true....

Add new comment

6 comments

Quite a niche and specific area but I want a mudguard mount for bikes without a chainstay bridge or braze on on the seat tube. All it needs is something to attach to a bottle boss, reach around the seat tube, a present a threaded insert for the lower mounting point of the 'guard. Currently using a zip tie which really isn't ideal (or neat) on a carbon frame.

If you could post here an image with exact full dimensioning in mm, I could try design it, export it as .STL file, post here a wetranfer link where you may print it at any 3D printing service in ABS or PETG material. No guarantee, but I can give it a try.

PS, Ti is not that expensive per kilo on a 10K bicycle like Moots, https://www.alibaba.com/showroom/titanium-price-per-kg.html don't let them fool you. Dropouts are complex and they just save manhours of craftmanship

Thanks. I'll see if I can get some time over the Easter weekend.

It could probably be as simple as a U-shaped bracket which attaches to a single bottle boss, goes around the seat tube on the non-drive side, and ends with a captive nut for the mudguard to screw into. Whilst you could do stuff like bracing/webbing it probably isn't necessary as it won't be taking any load, it's just to stop the unsupported end of the mudguard from flapping around.

I could make a prototype from a steel repair strip (like Mecanno) but wouldn't want to actually attach that to a carbon bike, I value my paintwork!

For now I've bodged it slightly using an Elite VIP ziptie bottle cage mount - see photo. Effectively what the bracket would do would be to provide extra clearance so the mudguard can be set lower (the ziptie approach means you have to locate it above the front mech braze-on). See photo.

On the subject of front mechs a perfect solution would be a modified band-on adapter, if the frame was a conventional straight tube. But this is primarily an issue on carbon frames with oversized BBs which don't have seatstays or round tubes down there.

Ok here is a first thought https://files.fm/u/euvdcjs7n you can download and play with it here https://www.viewstl.com/

In the image attached you can some of the dimensions used. If you are interested, make comments. mark on this image ALL possible dimensions (especially the exact dimensions of the nut and the bolt holes you will use) and I could possibly give it a try (no exact delivery time guaranted!)

Polycam is a decent 3d scanning app as well as another option. If you've no cash experience you could pop it on fiverr.com and take your chances there.

I haven't used this but seems promising. For the ones liking opensource Meshlab is a tool to create mesh from images.

But in kil0ran's case, I understand what he wants doesn't exist to scan it, so a new 3D model must be designed from scratch in CAD.