- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

3T Made in Italy frames DSCF4455

3T Made in Italy frames DSCF44553T brings its carbon frame manufacturing in-house to Italy

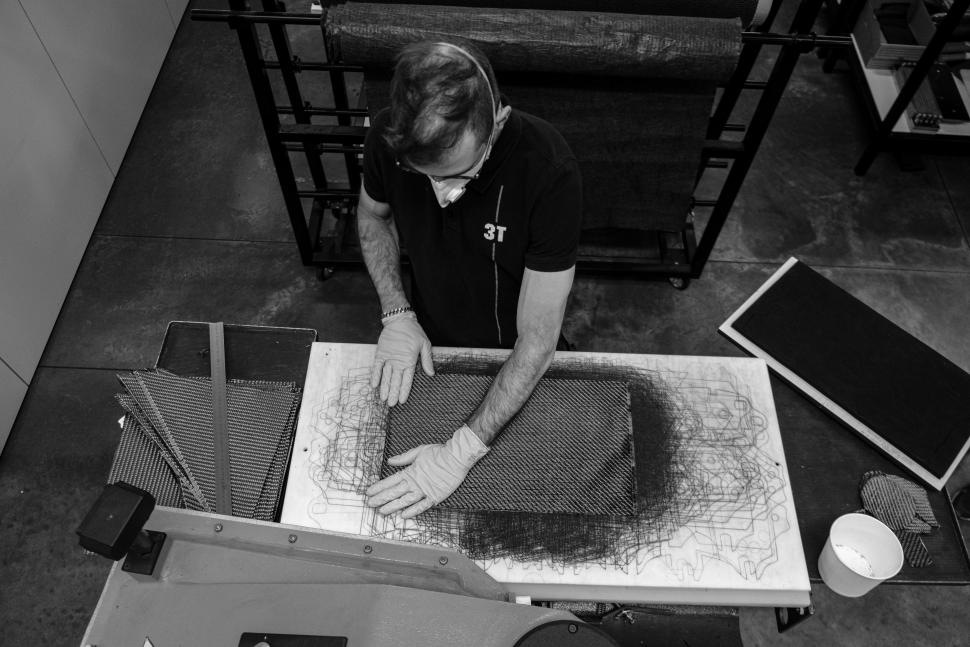

3T has announced it is moving manufacturing in-house with frames that are now 100% made in Italy using filament winding and dry fibre process technologies. There are also new limited edition Founders Exploro Racemax Italia gravel bikes on the way too.

The Italian brand has been making 3T frames first with the Exploro in 2016, followed by the Strada in 2017 (that bagged our Bike of the Year award for 2017/18), and it's now bringing frame production home after putting its 100% made in Italy Torno crank into production in 2018.

3T has targeted specific manufacturing technologies for the Italian carbon frame factory:

- Filament winding instead of manual layup

- Dry fibre and resin injection instead of pre-impregnated carbon

3T has designed and built its own filament winding machines and claims there are no limitations with regards to the fibres.

The Italian brand explains the process: “Instead of sheets of carbon cut in different shapes and applied on a core, filament winding uses a yarn is spun onto a core to create a carbon shape.

“By changing the speeds of the winder, you can change the angle of the yarn on the core.

“3T can create almost any layup with a combination of special fibre placement and cutting.

With the use of dry fibre 3T claims it can create more complex parts, integrate different types of fibres as well as add reinforcements where needed.

3T says there are advantages over using pre-impregnated carbon which can be energy intensive because of the repetitive heating and cooling cycle required. More moulds are also needed with pre-impregnated carbon to reach a high enough production volume because of the long cycle time.

With dry fibre, you can produce frame after frame without having to cool down the mould and heat it up again. 3T explains: “When you use dry fibre, you can stick it into a hot mould and nothing happens. Then you close the mould and inject the resin, at which point the resin starts the curing process.”

3T adds: “Every grade and type of carbon fibre is available as a dry fibre yarn.

“After all that is the base material used to make any other style of fibre – weaves, braids, UD (both dry or prepreg).

“The more you let suppliers process the fibres for you (by either turning them into sheets or tubes already or by pre-impregnating them), the more restricted you are in the type of fibre available.

“Having a production process that starts out with the yarn as we have now in our Italian factory means we can create the exact layup we want with the exact properties we want,” claims 3T.

The Exploro Racemax Italia gravel bike will be going into production this month, says 3T.

“The goal was to produce a frame that would be lighter than the standard Racemax (not that easy as it’s already light for a gravel frame) while keeping its stiffness and strength attributes.”

To celebrate the move to the new Italian factory, 3T is producing a special Founder's Edition from the first 100 frames. There are some pretty cool-sounding customisations:

- Engraved metal limited edition plaque with frame number

- Custom see-through paint options

- 2 finish options under the see-through paint (standard or industrial carbon finish)

- Customer's name under the clearcoat

- 1x+2x frame or dedicated 1x frame

The first frame will be on display at the 3T Museum, while the other 99 are available for £5,499.

Having left Sheffield and ridden through Wales, the couple opted to get a train from Wolverhampton to Oxford, where they were going to attend a...

That's some really really long fingernails you've got there!

It's not too bad. Most just make enough to get by and make people have to accept waiting or a different color. They know people are going to be...

Indepent drivel: I like it.

Cycling for mind: Some seriously shit steering there.

I like this sales attitude! Old style UK deprecation. "There are better brands - but try our pedals. Some people like them."...

The world's biggest violin, meanwhile I'm playing the world's smallest

You would like to think that 7 might make it a bit harder to ignore but I'm sure there will be a good excuse

Perhaps he followed the suggested Shimano online anti counterfeit link and saw that Shimano's opening header says "... crackdown in China.."?

Especially the fat ones.