- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

feature

MIPS visit - 3.jpg

MIPS visit - 3.jpgAll you need to know about MIPS

If you've been in the market for a bike helmet over the past few years, chances are that you've heard about MIPS and seen the (usually) distinctive yellow liners on the inside of some options that you've considered, so what's the story? What is MIPS technology and why has it become a feature of many helmets? I went to MIPS HQ in Stockholm, Sweden, to find out.

Bicycle helmets inspire strong opinions, to say the least. There are firm adherents who will wear one no matter what, and there are those who think the whole concept is a colossal waste of time. This feature isn't intended to persuade you one way or the other (I mean, if you want to argue the toss about it in the comments below, crack on), it's to explain what MIPS is all about to those who have decided that they do want to wear a helmet.

What is MIPS?

Let's start right at the beginning. MIPS stands for Multi-directional Impact Protection System and it's a safety feature that's incorporated into a helmet. MIPS is a low friction layer that allows 10-15mm of relative motion between the helmet and the head in all directions in order to reduce rotational motion transferred to the brain in the event of an impact.

That's the short version.

MIPS' basic argument is most helmets are designed to protect you from vertical impacts and avoiding skull fractures but they ignore more common angled impacts which cause rotational motion.

"Rotational motion is a combination of rotational energy (angular velocity) and rotational forces from angular acceleration that both affect the brain and increase the risk for minor and severe brain injuries," says MIPS.

"MIPS’ added protection system has been proven to reduce rotational motion when implemented in a helmet by redirecting energies and forces otherwise transmitted to the brain."

We'll come back to why rotational motion is important in a mo.

The MIPS backstory

In 1995, neurosurgeon Hans von Holst of the Karolinska Institute (a medical university) in Stockholm, Sweden, began looking at the way helmets were made. He thought that they weren't addressing rotational motion and contacted the Royal Institute of Technology in Stockholm to initiate biomechanical research.

Hans von Holst and PhD student Peter Halldin first developed the MIPS technology in 1996 and the first prototype MIPS helmet was tested in 2000.

MIPS originally intended to develop and sell its own helmets but it is now an ingredient brand that sells its technology to other brands. There's no such thing as a helmet from MIPS but you can buy a helmet that features MIPS technology from loads of big-name brands.

MIPS wasn't set up by any existing helmet brands. However, BRG Sports, which at the time owned Bell and Giro, bought a US$4 million stake in MIPS in 2014.

MIPS has been a listed company on the Stockholm Nasdaq Stock Exchange since 2017 and BRG no longer owns a large share.

More than five million helmets featuring MIPS technology were sold up until the end of 2017. You can now buy MIPS helmets from most of the leading bike helmet brands, including Bell, Giro, Specialized, Bontrager, Lazer, MET, Poc, Smith… There are exceptions; there are no MIPS helmet from Kask, for example. Check out thoughts from Kask down at the bottom of the page.

MIPS isn't confined to the bicycle world, it's also found in motorcycling, snow sports, ice hockey and military applications.

MIPS has 72 granted patents, most of them supporting the main one that enables 10-15mm of relative movement between two different surfaces, normally the head and the helmet. That's the basic concept of MIPS. Another 71 patent applications have been filed.

MIPS says that it has performed close to 20,000 helmet tests since inception.

What's the importance of rotational motion?

Hands up if you've ever come off of your bike. Okay, that's a lot of you. Keep your hands up if you knocked your head or bike helmet. And keep your hands up if you dropped vertically to the ground when you came off. The chances are that there was an angled element to it, right?

"Oblique impacts are the most common in most sports," says Peter Halldin of MIPS.

"The mean impact speed in a bicycle accident is between 6.0m/sec [21.6km/h or 13.4mph] and 6.5m/sec [23.4km/h or 14.5mph], the mean impact angle is 45° and the most common impact is with the road not a car.

"If there's an angled impact and if the coefficient of friction [between the helmet and the road] is high enough then we could get a tangential force. A tangential force will lead to rotation and the brain is very sensitive to rotational motion."

Rotational motion is something that scientists have considered to be important to head injury for at least half a century. It's not an idea that has come from MIPS; everyone agrees that avoiding rotational motion is crucial.

"In general, we can see that [when people hit their heads] there are two types of biomechanical injuries: linear and rotational," says Hans von Holst. "You have different types of fractures and contusions when you have a direct force at a 90° angle to the brain tissue, while rotational injuries include things like subdural haematoma and diffuse axonal injury."

Subdural haematoma (the most common type results from tearing of veins traversing the subdural space from the surface of the brain to the superior sagittal sinus, if you really want to know) is where blood collects between the skull and the surface of the brain and it can be life-threatening, while diffuse axonal injuries are where scattered lesions occur over a widespread area.

In short, rotational motion is bad news!

So what does MIPS do?

The aim of MIPS is to reduce the rotational motion in an impact by redirecting energies and forces. Compared to all that head trauma detail, the MIPS solution is pretty straightforward: a low friction layer is incorporated into a helmet that allows 10-15mm of relative motion between the helmet and the head in all directions.

Most often the MIPS layer is added to a helmet as an internal liner. You'll probably have seen them: made from yellow polycarbonate plastic, they sit between your head and the expanded polystyrene (EPS) body of the helmet. The idea is that in the event of an angled impact, the helmet slides relative to the MIPS layer and the head, reducing rotational motion transferred to the brain.

"When we started in 1996, to be honest, I had the wrong idea on why it works," says Peter Halldin. "At first I thought it was because MIPS spread the load over a larger area of EPS, so we got more EPS into action, and also that it was down to friction heat, but I was wrong.

"We did a very detailed numerical analysis of how the energy was absorbed or where it was disappearing. When a helmet impacts the ground the coefficient of friction means that the ground will 'grab' the helmet. If you don't have a MIPS system in the helmet, this will cause rotation of the head.

"But with MIPS we are mimicking landing on ice. What we are actually doing is redirecting energy. Instead of getting the rotation we let the head continue in the way it is supposed to go, so we are redirecting rotational energy into linear energy. A head in a helmet with MIPS will rotate less than a head in a helmet without MIPS. Of course, we do have some friction heat and we spread the load over a larger portion of the helmet, but I would say that 50% of the energy absorption isn't really absorption it's redirection.

"When we have an impact with the ground, the contact time in which the helmet can actually do something is 5-10 milliseconds, and for this very short duration the forces are like having 10 to 12 people standing on your head. That's why we need the MIPS layer to have a very low coefficient of friction in order to reduce rotation of the head."

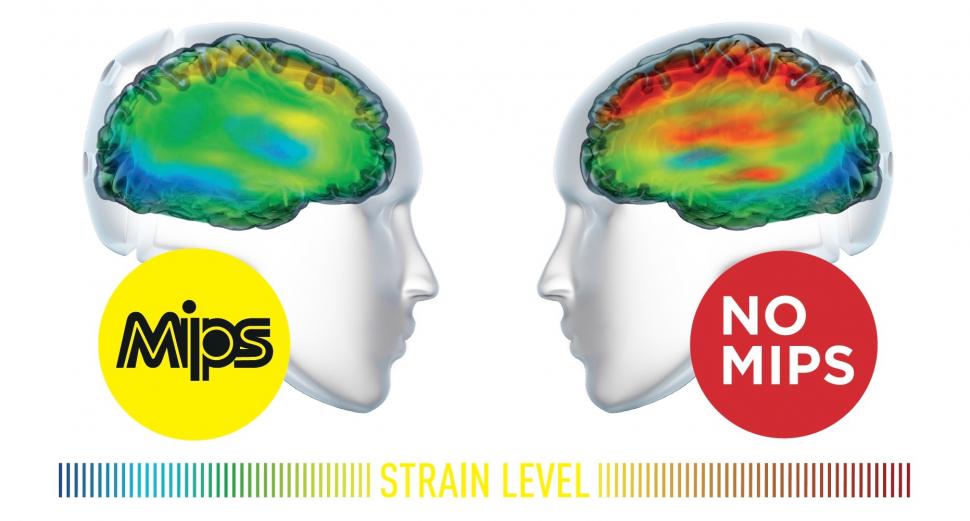

MIPS shows this illustration that has been generated using finite element modelling. It's based on data from accelerometers in a crash test dummy head that was subjected to angled impacts while wearing a MIPS helmet and a non-MIPS helmet. According to this model, there's far less strain on the brain with MIPS.

"We can't say that if the strain is over a certain level that you will get an injury, but we have models that are capable of saying that one helmet is better than another helmet," says Peter Halldin.

No one is saying that a finite element model is perfect, though.

"It is very good for comparing different product structures, but on the other hand it is so simple compared to a human being," says Hans von Holst. "It will take decades before we can simulate what happens on a cellular level when you have an impact."

The MIPS development process

Bike helmets come in various shapes and sizes, with different ventilation patterns and design features, so there's no such thing as a one size fits all MIPS system.

"The MIPS solution that works best can vary a lot between helmets," says Amy Pomering, product development engineer at MIPS. "With road bike helmets weight and ventilation are important as well as safety.

"In order to make the helmet as safe as possible there needs to be a lot of surface coverage, but if we cover all the vents no one is going to buy the helmet because it'll be too hot so we've not achieved much! There always has to be a balance while making sure that it lives up to our standards."

As mentioned earlier, most MIPS systems take the form of a polycarbonate plastic slip-plane layer that sits inside an existing helmet, but that's not always the case. The Giro Aether helmet (above), for example, uses MIPS Spherical technology, where the helmet is constructed from two layers of EPS that form the slip-plane system. In the event of an impact, these two parts of the helmet are designed to move relative to one another to reduce the rotational forces transferred to your head. This means there's no additional liner inside that might affect ventilation.

In most cases, a helmet brand will send a file of a new design to CAD (computer-aided design) engineers at MIPS who will then create the CAD file for the low friction layer. The helmets will already have passed the current test standards.

Then the helmets are produced and MIPS is sent models that contain the low friction layer in every size, along with their equivalents without the low friction layer added.

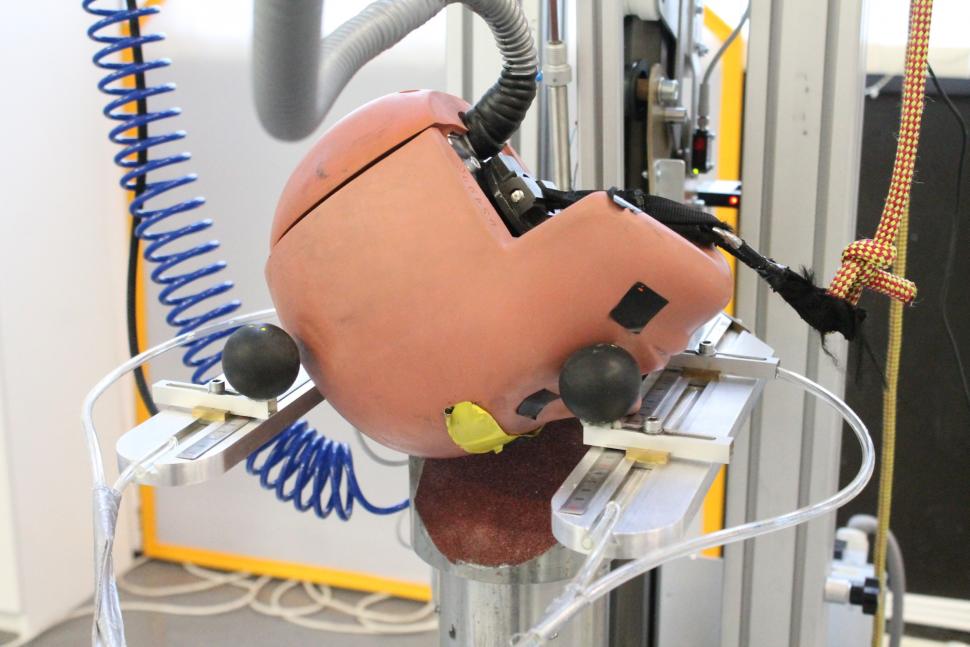

MIPS conducts its own oblique impact tests in the lab. It tests in three different impact directions to measure rotation in all three anatomical axes: X is forward, Y is to the side and Z is upwards. Every test is recorded with a high speed camera so that any unexpected outcome can be analysed later.

MIPS measures linear and angular accelerations over time and uses this information in the finite element model to compute strain within the brain.

"We compare the results of the helmets with MIPS with the results of the helmets without and are looking for a reduction in strain of greater than 10% in each axis," says Peter Halldin. "Normally we get reductions of 20%, 30% or even 40%, but 10% is the minimum.

"We might see a 50% reduction in angular or rotational acceleration with MIPS, but that doesn't really tell you about the risk of brain injury. To get an understanding of the risk of brain injury we need to look at the acceleration over time. You can handle a very high acceleration pulse for a very short amount of time, but the longer the acceleration is affecting your head the more energy and force is transmitted into your head and brain, so you need to take the time into consideration and not only look at the amplitude when evaluating the helmet."

How does MIPS affect price?

MIPS does push the price of a helmet up. A Giro Foray without MIPS, for example, retails at £69.99 while the MIPS version is £20 more expensive at £89.99. An Abus Viantor helmet is £90; adding MIPS takes that up to £110.

Is it clear cut?

Not everyone agrees, of course. They never do, especially where helmets are concerned.

According to helmet advocacy programme The Bicycle Safety Institute, "Lab testing using an unrestrained moving headform with a sticky rubber covering and no neck attached impacting a very rough 45 degree slanted anvil with the straps tight over an inflexible jaw (the configuration MIPS uses) has shown that MIPS does reduce rotational acceleration in that particular case. We still think your helmet, with a normal scalp under it, will move anyway.

"Do you need MIPS? Using careful evaluation, and in light of Snell testing showing no benefit in their test configuration, we are still not convinced that you do. It probably won't hurt, other than any effect on ventilation, of if your manufacturer has kept the same outer profile and reduced the thickness of the normal liner to accommodate the MIPS layer, or if it lets the helmet slip too much, or if the extra cost of the MIPS model makes a difference to you... We think the jury is still out on MIPS."

MIPS disagrees, of course.

"We have more than 17,000 tests done in Sweden showing that all helmets with MIPS are significantly better than helmets without MIPS," says Peter Halldin. "We do have scientific evidence that a helmet with a low friction layer will make a difference in a test including a tangential force."

The Swedish Folksam Insurance Group tested bicycle helmets and concluded, "Helmets equipped with Multi-directional Impact Protection System (MIPS) performed in general better than the others."

It must be said that the sample size was small, though: just 11 helmets. Folksam came to the same conclusion when it tested nine children's bike helmets and 15 equestrian helmets.

Virginia Tech, in collaboration with the Insurance Institute for Highway Safety, conducted tests (the methodology is here) on 30 helmets: 10 MIPS and 20 non-MIPS.

"Our bicycle helmet impact tests evaluate a helmet's ability to reduce linear acceleration and rotational velocity of the head resulting from a range of impacts a cyclist might experience," says Virginia Tech.

When ranked in order, MIPS helmets took up the top six places in these tests.

Putting safety issues to one side, some people have found that a MIPS layer can affect ventilation. Each MIPS layer is individual to a particular helmet design with gaps designed to allow vents in the shell and EPS to do their job, but riders sometimes complain that airflow is reduced.

This is less of an issue with a helmet like the Giro Aether which uses a MIPS Spherical system (see above).

The future

MIPS is developing new head forms because it believes the ones currently used in helmet testing aren't perfect. It also says that although today's helmet testing standards are helpful for measuring vertical impacts and for making sure you are offered protection from skull fractures, they should also measure more likely angled impacts.

"For this to happen we need some means of giving a pass/fail on rotational factors," says Peter Halldin. "We could use a finite element model and compute the strain although the models used differ so we're not ready for that yet, but I think new test methods will be introduced in the next few years."

Addendum: Kask's position

Since we published this article, Kask's PR has been in touch to make clear that its decision not to incorporate MIPS technology into its helmets isn't down to financial considerations.

Kask has made a statement explaining its position on cycle helmet safety saying, "Since 2012, major international regulatory bodies such as CEN, AU / NZS have been studying the subject of rotational impacts. Over this period, no regulatory body has adopted the testing protocols created by certain manufacturers that claim to demonstrate the value of their systems in absorbing the rotational energy created by oblique impacts.

"CEN (The European Committee for Standardization), however, is developing a method for measuring the absorption of energy from tangential (oblique) impacts, proposed by its technical committee on head protection. This group is known as the CEN TC 158 / WG 11.

"The WG 11 requirements will also be informed by evidence from several scientific publications and standards...

"All Kask cycling helmets have undergone this test and have exceeded its requirements.

"Starting from 2020, every new Kask helmet that successfully passes the CEN TC 158 / WG 11 test will be easily identified by a dedicated 'WG11 test passed' tag."

MIPS paid for the flights to/from Sweden and accommodation but had no editorial control over this article.

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- jamesha100 1 hour 2 min ago

I have been in Belfast for work this week and have been shocked by the congestion around the city centre. There are lots of frustrated drivers...

- David9694 1 hour 24 min ago

Cyclists should be made to have insurance etc https://www.thetelegraphandargus.co.uk/news/24757516.four-vehicles-seize...

- A V Lowe 1 hour 55 min ago

On a bus the driver has a fully glazed double set of doors that give a direct view of any cyclist or pedestrian travelling right into the left side...

- matthewn5 2 hours 21 min ago

A friend in my cycling club has a new Ribble Allroad, I think the model with 105, and when I asked how he was finding it (before reading this...

- Rendel Harris 2 hours 30 min ago

Well yes but that's if you're looking at an equation x = n x 3 where n is any number less than 5. If you're looking for a number that is three...

- check12 3 hours 47 min ago

Get them back? They've never gone away for me, cheap tdf winning bikes on eBay with rim brakes and cheap rim brake aero wheels, just don't tell...

- Simon E 4 hours 30 min ago

It used to be called Buy Nothing Day as a protest against the the Black Friday discounting madness. The constant BF adverts, promos and stuff...

- chrisonabike 6 hours 46 min ago

Apologies - you're quite right! Something about presentation and comprehension...

- wtjs 7 hours 6 min ago

You can find out whether they're lying about 'taking action' by asking them what they actually did. When they refuse to tell you, citing various...

Add new comment

13 comments

Digging up a year old article. I've been shopping for a new helmet for a couple of weeks with little success. What I have consistently noticed that's rarely discussed, is that MIPs versions of helmets fit smaller, the MIPs taking up space inside the helmet. If you are anything like me, with a large, long-oval head, then you'll find that you are already at the top end of the average helmet sizing as it is, throw in MIPs and every helmet I've tried is too small for my head in their largest size.

Giro and Bell are both too tight with hot spots front or rear depending on the model. I have a non-MIPs Kask Mojito that I bought around Xmas, tried on but never rode with it. Couple of months later when I took it out I found that it is both too large and too small - plenty of length and width, but inexplicably weird profile on the top surface that produces a pressure spot on the top front of my head, an inch or so back from my forehead.

I've never had much luck with helmets. I had an old Specialized back in the 90s that looked like Darth Vader's, but it fit. More recently the Specialized Propero II fits well but is so big the Storm Troopers snigger. My non-MIPs Bell Super 2 MTB helmet fits, just. I have my fingers crossed for the non-MIPS POC Octal that has just shipped.

I have a similarly shaped head.

It's a real pain to find a helmet that fits, and doesn't make you look like a mushroom.

Two helmets that worked recently were The Specialized Prevail (with MIPS) and the Lazer Blade (non-MIPS).

Thanks for that AMcCulloch, I am hoping you have made a fairly full recovery, took the drivers insurance company for everything you could and maybe, just maybe, ensured, through the law, that the driver might not do it to someone else?

I find my MIPS helmet to be a bit more squeaky than previous non MIPS helmets.

Here in Victoria, Australian we have what is called "Transport Accident Commission". It's a state insurance company and the premium is pay via registration on motor vehicle. It is a no blame insurance and it covers anyone who is involved in a transport accident, so it great when you're injured as they cover medical and wages, etc. It mainly cut out all the haggling in court, so more or less obsolves the driver of any financial burden in case of injuring another person. As for property damage you can go after their car insurance company but the insurance tend to dig in when it comes to bike and not pay out the claim, which means you have to take them to court and hope you win. For me it was not worth it.

Cheers

After a car on bike crash in 2011 where the driver was at fault I received a subdural haematoma plus a fractured neck (C7 anterioral). It seems the drive t-bone me and I went over the bonnet and hit the road head first, next thing I remember is the sound of the ambulance and then a pain in my neck, spent 12 weeks in a Halo.

Having time on my hands and angry with the world I delved in to the world of head injuries, helmet design and Australian dumb MHL. I looked at my injuries and wondered why the helmet failed, it was interesting to learn how they are tested and what they are design to protect against but also what they can't. I also discovered that helmet provide no protection from rotational injuries, which I received, but contribute to it by increasing the friction between the helmet and the road. Also the mechanism for concussion which can occur without the helmet even being damaged. I would draw your attention to American Football which has a high level of reported concussion, maybe a good area for MIPS to be tested in the real world.

So what I am saying is I applaud the effort to address rotational injuries but I put little faith in the ability of a bike helmet to protect my life with or without MIPS when it come to being hit by a motor vehicle an experience I do not want to repeat.

The helmet as always been the only solution to cyclist safety in Australia, MIPS may make a small difference but for me better infrastructure, better laws and better road education will go a long way.

Cheers

super article.

I'm a newbie- working on helmet design for only a year and see how crash protection seems to be 'worked in' or added into helmet design. The temple area of the skull is only 1-2mm thick, most road helmets seem to ignore this. The energy of the imact must be displaced. Conventional helmets did this by dissipating the energy thru the imploding of the helmet. This MIPS tech is a addition to safety, but when I see it on a few aero lids with only 13mm of EPS, I wonder is MIPS a marketing tool, rather than an answer to safer lids. They have got the branding on point and ran with it to the point now that consumers are forcing companies to use the tech.

Virgina Tech have a super imact test, but it negates air flow and useability. Would love to see smarter men and women than I decide an actual, global standard rating and test structure.... and then give us a standard BB and gear hanger once finished.

Best website for helmet data https://helmets.org

Leaving aside cycling to school, I bought my first road bike in 1986 and over the next couple of years crashed twice (first time didn't make it round a hairpin and the second time my front wheel caught the rear wheel of my mate in front) and had to have my head stitched up both times.

As far as I can remember, it was about 1989 that I saw the first bike helmet in the shops and figured it was a useful piece of kit so I bought one and have worn one ever since. I'll leave out falling off my mountain bike numerous times causing more pain to elbows and shoulders than damage to any of my helmets. The major incident was a few years ago, when rolling down a hill, I hit a hump in the asphalt without seeing it. When the front wheel hit it knocked my hands off the handlebar and I started to fall forward when, a fraction of a second later, the back wheel hit the hump and threw me clear over the front of the bike. I somersaulted through the air and landed on the back of my head and shoulder breaking a big piece out of the helmet. To suggest that that helmet did not save me from a serious head injury is up there with saying smoking doesn't cause lung cancer.

I know there are many scenarios where a helmut will not save you and I am not, in anyway, saying a helmet should be a legal requirement or that casual cyclists should wear one but anybody riding frequently/a lot in the 15-30mph range is daft NOT to wear one.

PS. Currently, I have the Bell Zephyr Mips. I'm a believer!!

Good, insightful, concise article btw.

surely the scalp moves 10-15mm. Im not sold personally

Not at the back or side of the head. Anything that can stop a coup being quite as serious has sold it for me. Especially with the price coming down so much

really? mine moves a fair bit, have you felt yours?

Fair enough but why wouldn't you want to potentially benefit from both? So far as I can see it is not an either/or.

Also many folk ride with an inner cap or now it's the winter season a beanie type skull cap. That should also provide potentially further dissipation of rotational forces between layers moving relative to each other but same question still stands, why not benefit from both or all three?

20 quid (extra) for MIPS on a helmet equates to a small round of coffee & cake for you and your mates. How much is head safety worth? Exactly.

You'd have to demonstrate that. Sure you can move your scalp around, but you need quite a lot of pressure on your fingers to do that. There's nothing to say that you helmet has anything like the same grip to be able to move the scalp, especially in the small time frame mentioned. I'm not saying MIPS definitely does all it claims, but your assertion seems to be based on less than solid suppositions.