- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Cross country mountain bikes

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

news

Video How To: Install a PressFit Bottom Bracket

Chances are that, unless you have been very lucky, you’ve heard that annoying click. It can start at any time. It gets into your ear and can ruin a ride faster than you can say ‘I might need to re-grease that’.

That annoying click has a source, it’s not always the bottom bracket, but the humble BB usually takes the flack. Generally this is because there are many BB standards, with several ways of converting between them and different cranksets after that. To be honest, it’s a bit of a mess.

Threaded bottom brackets are much easier

With that said, clicks and creaks can originate at chainring bolts, pedals, headsets, saddles, stems and cleats. It’s worth checking that these are all correctly torqued with the appropriate compound applied before we go blaming a possible innocent bottom bracket.

Let’s run through the most notorious clickers, the reasons they go wrong and how you can fix them.

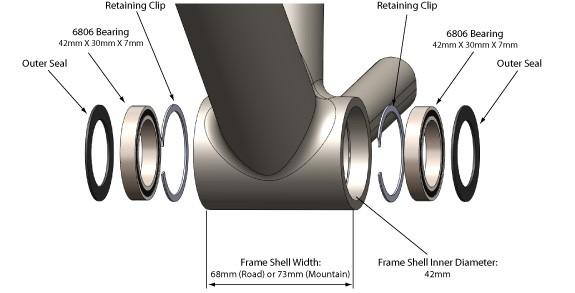

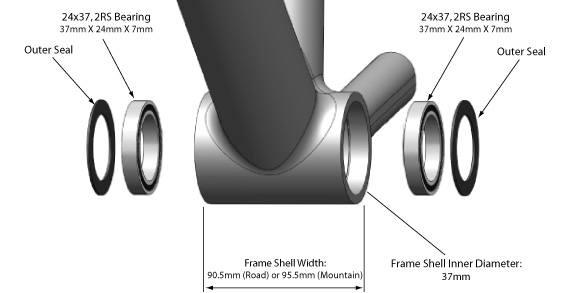

BB30/BB30a & BB90/BB95

Used by Cannondale and Trek respectively, these systems improved both stiffness and weight, but did lead to a few issues. Bearings are pressed directly into the frame.

Tech Specs

BB30 - 30mm axle diameter, 68mm shell width,

BB30a -30mm axle diameter, 73mm shell width with an asymmetrical design (5mm wider on NDS).

BB90 - 24mm axle diameter, 90.5mm shell width, 37mm internal diameter

BB95 - 24 mm axle diameter, 95.5mm shell width, 37mm internal diameter

Issues

Tight manufacturing tolerances means that is the frame mould is wrong, every bike that comes out will have a faulty bottom bracket. That’s not ideal for smaller manufacturers looking for as few returns as possible.

Clicks and Creaks

With bearings pressed directly into the frame, WheelsMFG suggest that “if your frame’s ID is slightly out of tolerance” even their crank adapters won’t fix the problem.

Park tool have recently released their new AP-1 Adhesive Primer and RC-1 Retaining Compound. When I spoke to Cavlin Jones, Park Tool’s Director of Education, he told me that securing the bearing in place is key to preventing creaks. He also made it clear that you need to use the AP-1, or the bearing will be stuck in there so tight, removal force could damage the carbon shell.

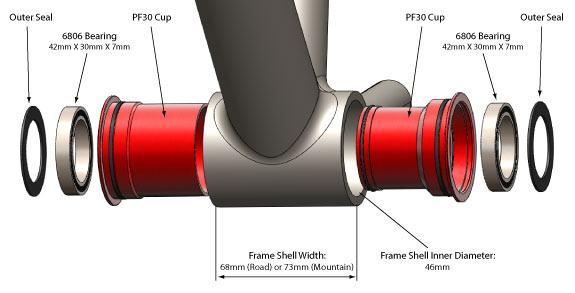

PF30

This widely used system is similar to BB30 with a 68mm shell width and 30mm axle. However, there’s an extra layer between with aluminium cups pressed into a 46mm frame shell and then the 42mm bearing pressed into that.

Tech Specs

30mm axle diameter, 68mm shell width, 46mm shell internal diameter, 42mm bearing external diameter

The majority of these systems use aluminium cups pressed into a carbon shell. Eliminating any slipping from here is key to keeping the system quiet. Just like the BB30 and BB90 systems, using Park Tool’s AP-1 and RC-1 will take up any space left through manufacturing intolerances.

But what if you have a BB30 or PF30 frame and want to run a Shimano crank, with a 24mm axle? Well, chances are, WheelsMFG have an adapter for that.

Clicks and Creaks

With another layer comes the potential for more things to click. Depending on frame material, different compounds are needed. If you’re pressing aluminium cups into a carbon frame, use the Park Tool compounds as above. Aluminium cups into an aluminium frame requires a high quality grease.

Bearing preload can also be an issue. Make sure your cranks are torqued to the correct setting, my Cannondale Si cranks being a whopping 40Nm.

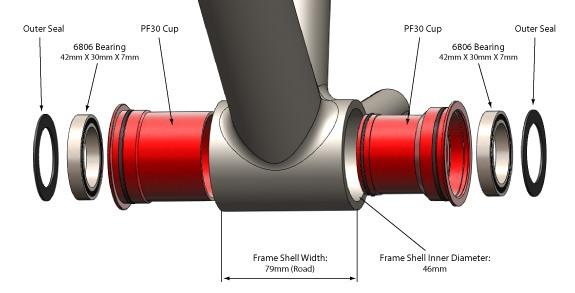

BBRight

Cervelo’s hybrid system aimed to take the best from pressfit and threaded to make a stiff, reliable and lightweight system. It’s essentially a wider BB30 which takes the 30mm axel and puts it in a 79mm frame shell. The super wide profile adds a fair bit of stiffness, but also allows for more clearance at the chainstays.

Tech Specs

30mm axel diameter, 79mm shell width, 46mm shell internal diameter, 42mm bearing external diameter

Clicks and Creaks

The wider shell puts a little less pressure on the bearings, but they will still click inside the frame if either the frame or bearing diameter tolerance is out. Use the ParkTool AC-1 and RC-1 to secure the bearing in place.

With all that said, proper maintenance can help to prevent clicks. So keep powerful pressure washers away from sensitive bearings and remember to fully service the bottom bracket throughout the year, especially if you ride in harsh weather.

Latest Comments

- LookAhead 3 hours 45 min ago

No matter what size tires can be fit with mudguards, it will always be possible to fit wider tires without mudguards. You literally can't make a...

- Sredlums 7 hours 54 min ago

I don't know how I can make it any more clear, so I will just repeat myself: "'I was not saying counterbalance isn't a thing"....

- Oldfatgit 8 hours 27 min ago

Won't she have to make a claim against the other party though?...

- Muddy Ford 9 hours 37 min ago

The Teddington Police Force must be extremely efficient to have stopped all the dangerous motorists behaviour in the borough that they can now put...

- Rendel Harris 10 hours 28 min ago

Looks a little bit like they stated "exclusive" to me...

- OldRidgeback 12 hours 44 min ago

If the Tour de France is to start in Edinburgh then part of the route should surely go through Little France?

- chrisonabike 14 hours 26 min ago

Ah, but they're used by crims! Feckless yoof probably dealing / stealing when they're not wheelying down the roads or pavements (is it them that...

- ktache 18 hours 18 min ago

I realised some time back, that if I was running a bit late at work and needed to get a wriggle on to catch the train, that I make up most time on...

- Rendel Harris 18 hours 56 min ago

In fact the last three Tours have started, respectively, in Copenhagen, Bilbao and Florence so the tradition of alternate years seems to have been...

Add new comment

20 comments

I don't think anyone is saying you should never use grease on a carbon frame, just that when installing a BB such as a PF30 with the plastic cups using grease won't help if you suffer from creaking, it will likely make it worse. You need something else to fill the gaps that lead to creaking or do it dry if creaks aren't an issue.

I researched the safety of using grease on carbon fibre and according to Jobst Brandt it's 100% safe, it has no affect on the resin at all. I used grease when I replaced the BB86 bottom bracket on my Giant although the bottom bracket is actually lined with an aluminium sleeve. The headset bearings sit directly on the carbon though and they get greased too.

Im just loving my old school Tripster V2 with threaded bearings. I have two bikes with presffit now converted to threaded bearings, no more creaks, clicks, ever . Pressfit was just a bad design, period.

. Pressfit was just a bad design, period.

Tools are a few quid if you decide to persevere with pressfit. Threaded bar, nuts, washers and punch. £10-15 all in

20160511_100152.jpg

It is just insane that there are so many standards.

I've had bottom brackets from FSA and Shimano inside my Giant TCX SLR 2, which uses a BB86 shell. So far I haven't had any problems with clicking or creaking, but I did have a local bike shop do the work.

Wheels Manufacturing has a pretty nifty universal bottom bracket press for US$35. They're a very good reference to the minefield that is bottom bracket standards, as well.

Without it you risk premature creaking and then you have to knock out and destroy perfectly good bearings. I used a little bit of blue loctite on a pf 30 (as recommended by FSA )and got a few thousand miles out of it before the creak started. I did have some trouble knocking it out so the primer is possibly a good idea. When I replaced the BB I decided to leave the loctite off and it creaked from the get-go so now I have loads of the loctite on and I am hoping to get many more thousands of miles of quiet cycling.

I've just watched GCNs Youtube video and they said you can generally just do this dry and didn't show any compounds. I have just bought a new BB, remover and press and was hoping to do it this weekend. How essential are these compounds [otherwise that is more expense and waiting, and wondering if they will denature or oxidize or dry out in the months and years before I need it again]?

Different people, manufacturers and mechanics will recommend that you do things a slightly different way depending on what you have. The golden rule is to avoid grease in a carbon frame. If you've got aluminium cups, I'd highly recommend a retaining compound. The plastic sleeves of Shimano PF86 don't need it as much but I'd say do it once and do everything to ensure it won't slip.

I've never heard of oxidisation occurring due to a retaining compound, I'd suggest it's more likely to happen using the dry method.

Okay so I was just about to chip in and say that I'd cured the creaking BB30 on my Synapse by using thick copper grease during reassembly and then read this...

Excuse my ignorance, but what's the issue with grease on carbon? Is it likely to cause problems? I fear I'm gonna have to go and dismantle mine again now, oh bugger...

I'm no Luddite but I really dislike press fit BBs. I have a Cervelo R5 and Campag Ultra Torque cranks. No matter what I did to ensure that the Campag cups stayed in the frame, the drive side cup would always walk out by 2mm or so - then stay there (I assume because the crank stopped it walking out any further). Tried the three recommended Loctite products, left the press in overnight, torqued up the centre bolt to spec, made sure the shell and cups were clinically clean... nothing solved it.

I ended up buying a Wishbone BB, which is basically a threaded BB but with the threads in the centre of the BB shell. All my problems were solved.

I have a Chrous cartridge BB in my commute/foul weather bike which has clocked up close to 25,000km. Still smooth.

Press fit BBs. Garbage.

Giant Defy Adv 2, got 200kms on it before click, creak, squeak..started getting really annoying at 700kms with a decided crunch during pedal stroke on drive side.

Clean/refit, clean/refit/replace...

now hopefully the Token TF24 screw together press fit will take care of the issue...

No prizes for guessing what I have to do this weekend...

20170328_170307.jpg

As with glueing tubs or doing internal routing, I find a bottle of Vodka makes the time fly by!

single malt for me

A 2L bottle of 'Bow is my default companion.

.

I did wince when I watched the bearing/ sleeve removal with hammer!

Once it's on, is there ever a need to remove the sleeves though? unless you're changing the make of crankset or bottom bracket maybe?

So for example using cups in a BB86 installation, I simply bought a £30 bearing press - the cups are housed permanently in the frame and you just remove the crankset, upon which the bearings are mounted

(OK a bearing change then needs an extractor and installer tool to change bearings but a job I do fairly regularly across both bikes so worth the £50 for those).

It strikes me that the more layers with sleeves / adaptors / shims you need, the greater the liklihood for creaks. The BB30 as demonstrated in the video had sleeves that lock together in the middle. I'm unsure of the exact mechanism, but as this doesn't screw in presumably that's another potential source of creaking?

The problem with bearing sleeves is that not all are perfect in the frame. Mine was slipping under load on the drive side. The only way to get a retaining compound in there to take up that space is to remove the whole system. Ideally, yes, you'd only ever have to remove the bearings but age affects all bikes and sometimes you've just got to.

Correct me if I'm wrong, but BB86 uses a composite plastic sleeve(?), that's what I've seen on Shimano systems anyway. I don't know why but these have always been much more reliable in my experience. Maybe it's a slight flex or the absence of metal on metal? What I know for sure is that the sleeves in this system can be removed, quite easily in fact, although I only had the need to after around 13,000miles.

You are completely correct that more layers are just a chance to click and creak. The point in the middle, where the two meet shouldn't creak as there is a rubber ring that separates the two metal pieces. With my experience of layered systems, especially the Cannondale system, I've been looking at how to run a different system. I'll probably be getting the "PF30 OUTBOARD ABEC-3 BB FOR 24mm cranks" when I can upgrade my power meter to a 110bcd P2M Dura Ace 9000. Until then, I'm a little stuck with what I've got, although it's working perfectly... for now...

Ah OK mine is Campagnolo ultra torque with special small metal cups pressed in. There, the original bearings are untouched, still in the same place as you'd use on a conventional threaded BB, only they're brought inboard by the wider shell.

Fortunately no creaking yet. But it's still an aftermarket solution / 'bodge' compared to the original threaded system, albeit seemingly an effective one.

I don't ever want to have to remove the cups though - they're in tight!

unless you are doing this a lot the cost of the right tools for the job (drift, press) are going to outweigh giving it to your LBS really. I'm talking for BB30 a £30 puller and £50 press (both from Park) on top of circlip pliers and however much you pay for the bearings. on top of the risk of damaging the frame and having no-one to complain to but the mirror it just seems like a faff.

Speaking as the owner of 3 BB30 bikes in the past that all needed BB changes regularly so I did get the tools.