- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

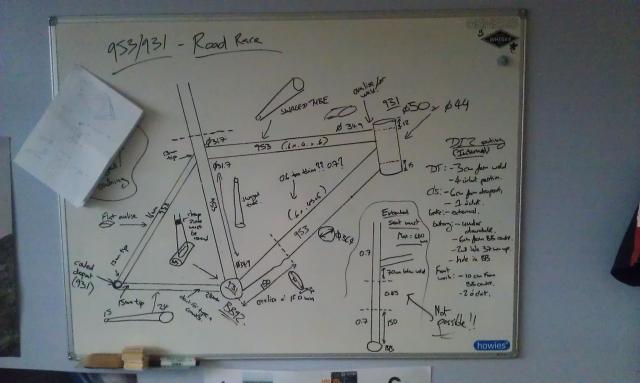

TECH NEWS

Madison Genesis

Madison GenesisTeam Madison Genesis’ steel Genesis Volare

Team Madison Genesis rider Ian Bibby piloted the new Genesis Volare to victory at the IG London Nocturne at the London Bike Show earlier today, proving that a steel bike can still cut it against carbon. We showed you a prototype the other day but this is the version that Team Madison Genesis were showing when the team was launched to the public at Excel.

Designer Dom Thomas gave us details in that article (link above), but we’ve also spoken to Chris Snook about the bike. Chris is in the unusual position of working for Madison, who own the Genesis brand, and riding for the team, so he has been following the development of the bike from the initial concept right through to the finished product.

road.cc Can you tell us about the material used for the Genesis Volare?

Chris Snook The team race bikes will be made from Reynolds 953 which has an extremely high strength-to-weight ratio. We will be using the widest tubes available for the down tube to gain maximum stiffness. Using a wider tube also makes for a lighter tube. This is because the increased diameter means that you can get away with using a smaller wall thickness (0.4mm in places).

The training bikes will use Reynolds 931. The bikes will share identical geometry, but the tube profiles will be slightly different.

Was the tubeset developed especially for this bike?

We are using a custom tubeset specifically made for Genesis and this race project. We are taking steel to the limits of its capabilities. The tubesets have to be formed by Reynolds in Birmingham as they are the only people who are able to swage – make narrower – and ovalise the tubes that we require, due to the oversize tubing we are using.

The top tubes are swaged at each end and also ovalised. This allows us to use an oversize tube and to maximise the weld areas for increased stiffness. The down tube is also swaged and ovalised to meet the bottom bracket, again maximising tube diameters and weld areas.

We use pencil-thin seat stays to provide stiffness – more swaging as they meet the chainstays. The chainstays themselves are massively oversized, and swage from 24mm at the bottom bracket to 15mm around the dropout. The chainstays are ovalised to allow extra tyre clearance, rather than crimped, to eliminate a potential for fatigue.

Lastly, the seat tube is swaged from 34.9mm at the bottom bracket shell to 31.7mm at the top and then shimmed to allow us to run a 27.2mm post for comfort.

The head tube looks chunky…

It’s an XX44 standard, which is the lightest way to run a fork with an oversized steerer. XX44 itself was originally designed with Reynolds and Genesis. It is a standard that is being used increasingly in the industry. The bottom bracket is BB92. This uses an oversize shell and a press fit bottom bracket. Not only does this increase stiffness and reduce weight, it also provides the all important weld area.

The mechanical bikes will use external cabling, but the Shimano Di2 (electronic shifting) bikes will be fully internally routed, with the battery mounted on the chainstay.

How long has the bike been in development?

The concept has been on the drawing board for at least 18 months. That’s how long it has been since I first heard about the idea.

And it was designed by Genesis’ Dom Thomas?

Yes, it’s designed by Dom. It has been a two way process with him saying, “I want to do this,” and then Reynolds come back and saying whether it was possible, and if not, what could be done instead. Both parties have been pushed by the concept.

Has there been much input from other riders?

Like all Genesis bikes, there is a degree of testing internally. However, the team has allowed us (Genesis) to gain feedback from the riders. I was given a prototype 953 frame to ride last year, and Andy [Tennant] was given a 931 one. We have both been giving feedback on the bike which is being incorporated into the design.

The rest of the riders had bikes at the end of last year, and they have also been giving their input. The frame is still under development, and you may see a few tweaks to geometry over the early part of the season. Prototyping is key to this project, as there is so much that hasn't been done before.

What equipment will the team be using?

We’ll be using Dura-Ace 9000, with a view to moving across to the 9070 [Di2] groupset when that becomes available. We will be riding Shimano wheels and PRO finishing kit.

Being Madison sponsored, we have a number of brands supporting the team – Giro, San Marco, Elite K-Edge, GoPro... We also have external sponsors in Volvo UK and Little Trees.

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- Disgusted of Tunbridge Wells 2 sec ago

Not sure if I missed it but I didn't see anything about aero gains, weight savings and they didn't look that "cool" either???...

- Steve K 8 min 8 sec ago

How many of those rides were previously done on normal bikes?

- eburtthebike 4 hours 47 min ago

Newspeak:...

- eburtthebike 6 hours 54 min ago

As Ranty Highwayman says, an eight minute presentation of everything that is wrong with UK highway design, starting from the premise that...

- Dnnnnnn 8 hours 26 min ago

I can see you've had a look at the Inverness Tourist Board Facebook page...

- Piratepete 8 hours 36 min ago

The Police Scotland Digital Evidence Sharing Platform being rolled out will not make it any easier to report incidents, it simply allows an...

- Rendel Harris 10 hours 33 min ago

Highway Code states: ...

- hawkinspeter 14 hours 36 min ago

I do indeed.

- Jakrayan 14 hours 45 min ago

The article states the toerags were youths, so unfortunately there probably won't be any real punishment. But at least the police are appealing for...

Add new comment

30 comments

Having seen them at the Bike Show it is a really nice looking frame. Very smooth tidy welds and great looking (lettering aside).

It's not about the bike is it.............but who's riding it

I now dread to think how thick the tubes on my steel steed are. Though it does weigh an absolute ton so i'm probably ok.

Thats a bike I would love to own and race. British too. Anything even around 7-7.5kg is a light bike. I imagine that is a real pleasure to hammer on. I want one for Xmas please. It would be a shame if the exact tube set is not available for us lemmings

A beautiful bicycle, but then I am a steel evangelist. Can anyone answer my cyclo-thicko question - would there be any possibility of Madison Genesis racing in the Tour of Britain this year?

A top-end bike build can easily get under 6kg these days, so in order to race it, the choice of adding 800g of ballast or 800g of frame weight (in order to make the 6.8kg minimum) really makes no odds.

Looks awesome.

Pretty sure 1kg costs you something like 25 seconds on a long alpine climb (source: Lance Armstrong) so <=800 g's on short climbs will probably make v little difference. But a difference non the less. ( I specced this frame up with some fancy kit and came out with a 6.8kg weight)

Lovely colours, absolutely shocking typography. It takes something really classy and makes it look really clumsy. It looks like someone just threw logos at it until they ran out of space.

Sounds like a small thing, but IMO Condor's Super Acciacio looks way smarter as a result.

I think you just described pretty much any pro-team bike design strategy there

Agreed. But they have been making theirs for Rapha-Condor riders since 2010? They have had time to refine it.

What fork is in the Genesis. Some riders had a curved Easton fork and others had a straight fork?

you *can* go down to 0.2mm with certain steel and alloy tubesets

Wow, that's amazing. If a bit scary. Surely having a heavier frame would allow you to reduce rotational weight more? Lighter wheels and cranks, which would, as far as i am aware, be advantageous?

All of the super light bikes that are used in Pro racing must be miles and miles lighter than the UCI weight limit anyway so frankly a frame being 1kg lighter just means they don't need to find things to weigh it down with.

I don't think that's true. Geraint Thomas' Pinarello was weighed recently at 7.76 kg. So this frame is certainly competitive in terms of weight. That said, Pinarellos are at the heavy end of the pro bike spectrum.

Weight is very important in pro races in that no one wants a weight penalty over another rider. No rider will be happy with a bike that is 400g heavier than a competitor. It's true that such a figure is marginal, and will make little difference to us lot, if you're paid to race it's a different matter

0.4mm?! Is that a misprint that should read 0.4cm or do the tubes actually go down to approximately the width of this full stop. ?

It's 0.4mm, karlowen.

Japanese tube manufacturer Ishiwata used to make tubesets named after their wall thickness in thousandths of an inch. The lightest was 015, then there were 017, 019 and 022.

There are 39 thousandths in a millimetre, so 015 was about 0.4mm. The danger is denting it.

Saw Bibby win this.

What a beast.

Well - it seems they have just won the very first race they have entered in so that 800g clearly isnt a problem!

Looks nice, like the colours...

Im not expert so can anyone tell me what the extra weight of 800g realistically means to a pro rider?

Its a beautiful bike but we hear a lot about marginal gains - i personally think the tiny weight differences that are involved, over the course of a race or tour , are meaningless - but am willing to be put right.

I have the greatest respect for Genesis using steel and as i said its a beautiful bike but if the weight is an issue and prevents them winning races will it all be in vain? I hope not.

Did i mention that i think its a beautiful bike?

We're not sure what complete bike weight they're at right now but it's unlikely they'll be far over the 6.8kg minimum limit when they're done. It's really not going to be much of a factor.

IIRC Nick Legan, who has worked as a mechanic for RadioShack, Garmin, CSC, among others, and who now writes for VeloNews, has written that most pro bikes at the top level comfortably gets under the UCI weight limit as it is, so there is a little extra margin so that the riders can choose the saddle, pedal, bar and tape combination that they like and not be too concerned about weight. For the same reason a lot of pros use solid chainrings and power metres on their race bike - the benefits are often marginal, but since the bikes are under the limit anyway, why not?

So I don't think the Genesis will be too far above the weight limit anyway, and even if it is at the end of the day, say 200g heavier than the average carbon bike, that's still only a fraction of one percent of the total mass of rider + bike + kit + water bottles, a non-rotating mass at that. I imagine things like riding position, tyre and wheel choice will matter much, much more.

The frame is about 1700g, so it's going to be about 800g heavier than an equivalently specced carbon bike

Reynolds 953 has indeed been around for a few years, but Genesis are attempting to push the tubeset closer to the limits of lightness and stiffness. It's very different to the currently available 953 tubesets

I might be wrong but Brian Rourke has been making beautiful frames from 953 for a while now.

weighs 6.7kg?

Nice looking bike and subtle paint works well.

Is this going to be a production bike with the same spec tubing?

At the reported weights it would be a real option for someone looking for a light non-carbon race ready bike. It would need to be built up with decent light weight wheels and gruppo but at least it would offer something more durable/repairable than carbon.

More durable, yes, more repairable, probably not. 953 is pretty difficult to work with, and I'd think you'll have a hard time finding many builders who would want to repair a damaged one. That said I'm a little disappointed that so far there has not been more than a trickle of 953 frames on the market, as I quite fancy buying one myself and has been waiting for the price to come down a bit.

Yes tricky to repair welded frames, but quite easy on lugged frames. A material that is difficult to work with and only used by very skilled builders, means that there is a trickle of very nice bespoke frames, so you may have long wait for the price to come down a bit when most builders have a year or so waiting list. Also 953 is the only tubing still made in the UK by Reynolds, so it's a premium product used in hand-made frames and not churned out of Far East factories like your average (and expensive) over-priced carbon clone.