- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

Genesis Volare Team - seat tube badge (1).jpg

Genesis Volare Team - seat tube badge (1).jpgCaterham uses Reynolds butted bicycle tubes to develop new Seven sports car

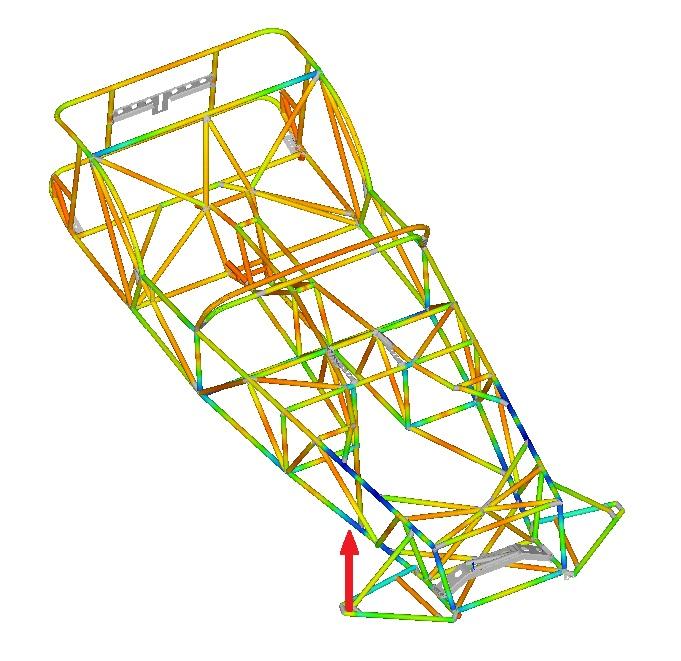

Sports car manufacturer Caterham is utilising Reynolds butted tubing in the development of its new Seven sports car, with a 10% weight reduction in the new space frame chassis that is being trialled.

Butted tubes, first pioneered by Reynolds way back in 1898, are common on steel, titanium and aluminium bicycle frames today. Butting involves increasing the tube wall thickness at the ends, and making them thinner in the middle, which results in a lighter tube while retaining strength at the junctions.

- Trend spotting: Is there still a place for steel road bikes in the age of carbon fibre?

The bicycle industry takes butted tubes for granted, well on more expensive bicycle frames at least, but in its application of butted tubes, Caterham Cars is claiming to be “spearheading a project to build the world’s first space frame chassis using butted tubing technology.”

Caterham is collaborating with Reynolds Technology and computer-aided engineering consultancy, Simpact Engineering, on the project to turn the new chassis into reality by February next year, with the development of a prototype car based on its iconic Seven.

The Caterham Seven was launched in 1973 but was based on the Lotus Seven designed by Colin Chapman in 1957. The Seven was a lightweight and affordable sports car that has become an iconic symbol of the benefits of low weight. Chapman’s design philosophy was to subtract weight instead of adding more power.

The motoring industry has been pushing towards lowering emissions over the years and decreasing the weight of the car is an obvious benefit. “The automotive industry is under huge pressure to provide more solutions to make vehicles lighter and decrease emissions,” says Simon Lambert, CTO of Caterham Cars.

He adds: “This is something Caterham has been doing since inception more than 40 years ago, thanks to Colin Chapman’s original ethos of ‘adding lightness’, so we are well-placed to undertake experiments in this area that could benefit the much wider industry.”

Keith Noronha, from Reynolds Technology, said: “Our butted tubes have contributed to weight reduction in diverse applications from bicycle frames to NASA spacecraft projects. This project aims to prove that car designers can re-think how to use steel - a sustainable and recyclable material – whilst meeting challenging targets on stiffness and driveability. The Caterham Seven should be the first car to incorporate these innovative aspects.”

Caterham has received grant support from the Niche Vehicle Network, which offers support to the UK’s niche and specialist vehicle manufacturing sector.

So you never know, the car of the future might owe a little to the humble bicycle frame.

David worked on the road.cc tech team from 2012-2020. Previously he was editor of Bikemagic.com and before that staff writer at RCUK. He's a seasoned cyclist of all disciplines, from road to mountain biking, touring to cyclo-cross, he only wishes he had time to ride them all. He's mildly competitive, though he'll never admit it, and is a frequent road racer but is too lazy to do really well. He currently resides in the Cotswolds, and you can now find him over on his own YouTube channel David Arthur - Just Ride Bikes.

Latest Comments

- Rendel Harris 3 sec ago

And bang on cue, from the Guardian just eight minutes ago…

- Bungle_52 16 sec ago

I was wondering why the prosecutor used the word ordinary rather than competent. The two seem completely different to me.

- Paul J 2 min 18 sec ago

Bizarre isn't it?...

- Jaijai 59 min 2 sec ago

I'm surprised ,the ones I've seen 8n and built have all needed paint overspray pretty much all areas ,including headtube ,brake mount areas wheel...

- quiff 2 hours 4 min ago

Interesting. I would have expected someone else (wearing gloves) to handle the swab and administer the test to minimise that sort of contamination....

- the little onion 3 hours 32 min ago

The bus should have been bigger and brighter coloured. How are drivers expected to spot a bright yellow double decker bus on our roads?...

- HoarseMann 4 hours 24 min ago

BBC news article on this implies anyone cycling on the road, rather than using the cycle area, is riding incorrectly! ...

- festina 5 hours 49 min ago

One thing that definitely doesn't hold up emergency vehicles is the volume of car traffic on the road or the autobesity of cars that has been going...

Add new comment

5 comments

FFS! Some of the comments on here are getting sadly predictable. I'd recommend spending more time riding your bike(s) than clicking through to articles that you'll clearly have no interest in.

F*** the naysayers, as someone who loves bikes and cars I found this article rather interesting.

What exactly has this to do with cycling, road or any other variety? Because they are using Reynolds tubing to build this particular death machine? My neighbour has a nice selection of old bikes as garden features - gonna do an article?

Why the anger you muppet? Click away or dont read it.

“The automotive industry is under huge pressure to provide more solutions to make vehicles lighter and decrease emissions,”

yes, and in the next iteration of this design there will be only two wheels and pedals; so the incredible goal of reducing emissions to zero will be reached ; but with style !