- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

DT Swiss 240 EXP Rear Straight Pull Centre Lock 2

DT Swiss 240 EXP Rear Straight Pull Centre Lock 2DT Swiss acknowledges issues with Ratchet EXP hubs

DT Swiss has publicly acknowledged an issue with its new Ratchet EXP rear hub internals where the premature wear of the ratchet drive rings caused restrictions to the engagement in some cases.

> Your complete guide to DT Swiss wheels

Hubs affected

DT Swiss standard products:

- ARC 1100 / 1400 DICUT

- PRC 1100 DICUT Mon Chasseral

- XRC 1200 / 1501 SPLINE

- XMC 1200 / 1501 SPLINE

- EXC 1200 / 1501 SPLINE

- 180 Components hub

- 240 Components hub

- SERVICE KIT RATCHET 36T EXP W/O TOOL

- SERVICE KIT RATCHET 54T 180 EXP W. BEARINGS

- SERVICE KIT RATCHET 54T 240 EXP W. BEARINGS

- SERVICE KIT RATCHET 54T EXP W/O TOOL

What does this mean? Essentially the ratchet rings that usually engage when you pedal - but slide over each other when freewheeling - have in some cases been wearing out, and eventually failing to engage when you go to pedal. That’s far from ideal as you’d be left unable to go anywhere.

Initially, DT Swiss says that they were not able to explain what was causing the issues. After all, their Star Ratchet technology has been working incredibly consistently for years, and DT Swiss has rightly earned a reputation for producing bombproof hubs.

The issue, DT Swiss believes, has been identified: "Variations in the surface finish of the ratchets that are in a completely normal range for the traditional and established systems are potentially leading to premature abrasion of wear parts in the new Ratchet EXP system," it says.

“This premature wear can then lead to restrictions of the engagement in individual cases, which can be remedied by a simple replacement of those wearing parts.”

If this is indeed the case then it could be a simple issue to fix, but could potentially have much more troubling implications for DT Swiss. The good news is that the ratchets are a relatively inexpensive part of the hub. This is also a rather easy part to replace and owners of affected hubs should be able to perform the replacement at home should they have decent workshop skills.

The worry comes with the phrase “in a completely normal range for the traditional and established systems.”

This is a far more concerning issue for DT Swiss, as it could suggest that there may be an underlying issue within the Ratchet EXP hubs. This could be causing the ratchets that worked just fine in the old hubs to, in some cases, fail in the new hubs.

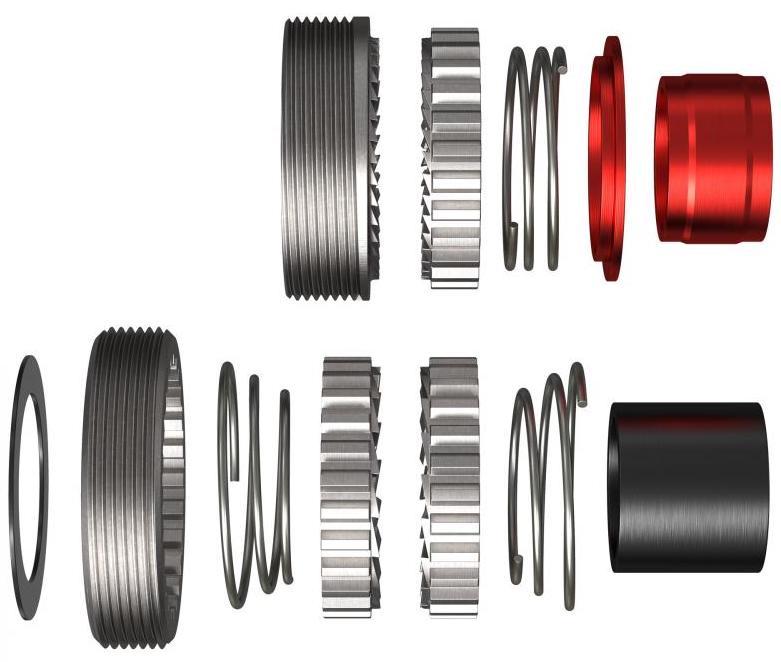

The new DT Swiss 240 Ratchet EXP hub moved to a system that requires only one spring to align the ratchets, whereas the previous system required two conical springs. This, DT Swiss claimed at the time of launch, “results in faster full engagement and eventually reduces wear.”

> DT Swiss 240 EXP hubs claim 15% improvement in axle stiffness

While in the short term DT Swiss can ask owners of the affected hubs to keep an eye on their wheels and replace the ratchets should any issues arise, they will want to find out why a part that worked well in the old hub is now prematurely wearing in the new design to avoid a potential dent in its reputation.

While DT Swiss lists the above hubs that should be checked, there is no word on OEM brands that use DT Swiss Ratchet EXP internals.

DT Swiss has provided a link to its service manual, explaining how to disassemble the hub and how to inspect the ratchets for wear. The official advice, however, is to take any wheel that doesn’t appear to be working correctly to a DT Swiss service centre for a free inspection, or contact them here.

Latest Comments

- wtjs 3 min 17 sec ago

Is it really about the bikes, or is it actually about the people riding them? ...

- polainm 5 min 2 sec ago

Wilkinson is such a polished nob no amount of sleep could undo his track record of rabid hate articles. Our hope is his sedentary lifestyle catches...

- Destroyer666 21 min 47 sec ago

I think someone at the office has pulled a prank on less informed road.cc reviewers: First a review of Effetto Mariposa's helmet liners and now a...

- hawkinspeter 1 hour 3 sec ago

Disabled woman left in tears over Liveable Neighbourhood as residents demand apology:...

- Sredlums 1 hour 8 min ago

On Instagram, user @wheel_based (who has very interesting posts covering cycling patents) mentioned that hands saddle and said he would try to buy...

- Sredlums 1 hour 23 min ago

Props for weighing in the environmental concerns.

- tony.westclassics@live.co.uk 1 hour 25 min ago

If your running 11 speed, Shimano chain will run with Campag

- brooksby 3 hours 21 min ago

A picture: (edit) Hmm, it's the right way up on my phone...

- muhasib 8 hours 39 min ago

"Clunie, who was stopped at the lights at the time of the crash,"...

- Miller 12 hours 20 min ago

I'm reading this as the komoot founder cashing out? Tough on the staff who'll get a redundancy notice and not a payout.

Add new comment

18 comments

I can't say that I'm surprised by this coming from DT Swiss. I worked on wheel design in the bike industry 15 years ago. Our hub partner was DT swiss and we had constant problems with them. We had issues with many components including ratchets. What was always common was that it was never their fault....Typical dishonest Swiss Germans . Good Luck with getting any compensation out of them, they are as tight as they are dishonest

Nice stereotyping there.

It is just plain reckless to make generalizations about groups of people based on where they come from. Then again here I am making assumptions that hasbeen bike designers turned bitter internet trolls are a lesser group of people.

I never went back to see if the racist comment left on something the other week was picked up on or not. (TBH, can't remember the topic either). But I suspect they don't looks at all comments so anything considered "dodgy" either needs to be stumbled upon or reported to them.

Happened twice to me now. First time put it down to unlucky. £50 service kit fitted. 6 months later the same. Put it down to age of wheel and maybe time for new ones. I’ll be on to DTSwiss for replacement under warranty now. Pretty poor to say just service yourself.

I notice that Newmen have changed from using a ratchet system back to using pawls. Their gen 1 hubs used a ratchet, the later model Fade hubs use pawls.

Honest question: what's the difference?

Don't ratchets work with toothed wheels and pawls ?

"The good news is that the ratchets are a relatively inexpensive part of the hub. "

Sort of but, last time I looked they wanted about £80 for one set of ratchchets and springs.

Funny seeing DT Swiss admit that they have an issue with a product. 😆 Normally they just pretend nothing is going on and have their customer support at the distributors sort i out.

This issue also happened on brand new non-EXP hubs for years, although they never managed to explain why it happened. Although on the old hubs it was only a few cases a year on thousands of wheels sold, so no big deal. But a bit of a pain in the behind if you are standing in the woods, 50 km from your car and your ratchet system decided to give up. 😕

What is it with hubs? Most seem to have 1 issue or another. Must be the sketchiest part of a bike. Don't put bike engineer on yer CV!

Usually it's either poor design, not fit for purpose, or just poor quality and made down to a price.

Making hubs that last is not an easy task. A lot of the simple hub designs worked well enough when we had small cassettes and simple drivetrains. When you start to add huge range cassettes, 9t cogs, 148mm wide hubs and e-bike motors with 100Nm of torque, things get a little more complicated. 🤔

Another thing is that nobody wants a very heavy hub, or hubs with a lot of drag, so compromises are made.

After 150 years you would think we would start to get the hang of it though...

If cyclists got over their weight fixation a little, maybe things like hubs would last.

We want lightweight stuff that lasts, but aren't willing to pay much for it. Because likely longevity is something that is pretty hard for a consumer to judge (without understanding the engineering behind the product and being able to inspect the internals), 'lasts' is the thing that tends to give first.

And I know DT Swiss stuff is far from the cheapest option out there, but they like most companies will be building to a price point.

You saying I'm fat?....

What is it with hubs?

And yet, basic cheap Shimano (other hubs are available) or un-named hubs just work without trouble for decades. I have Ultegra and Dura-Ace hubs 30 years old still working normally which come up shiny with just a bit of a rub. I have un-named hubs on my excellent £650 9-speed Vitus Substance gravel bike which seem fine to me (black, so no polishing) and where I overhaul people on descents without pedalling, although this could be connected to the weight in the trailer. These hubs have ball-bearings so I am fairly confident about their longevity. I think basic stuff is getting better, and maybe it's the posh tricksy light stuff which causes problems?

I think the Shimano freehub is one of the highest points of bike engineering, a sophisticated and durable design. The Campag hubs I use are beautifully made, but fatally flawed in key areas of the design, by comparison. To me, everything else just looks... dubious.

a cone & cup bearing like shimano like to use are a much better engineering solution as they are conical and therefore take the inevitable side loads. I've not seen anyone employ conical cartridge bearings. However, I'm not a fan of cup/cone as the cone is rarely a replaceable part, and if water gets in pits in the cone are inevitable and that's a new hub. So I find shimano flawed in that way, other than that, they are buttery smooth and reliable.

I completely agree-the placement of the drive side outer bearing is genius; and no matter how old a shimano hub of mine is, whenever I've opened it up the grease seems to be largely uncontaminated, with bearings in good condition.

I gave up on Campagnolo hubs as the single, hair thin, circumferential pawl spring repeatedly gave up the ghost.

But the old shimano with the small diameter steel spindle, once they put in the fat ali one the freehub innards got smaller then they started to fail on me quite regularly. XT (touring).

They were easier to adjust too.

The seals got a lot better in the 30 years I have been using them.