- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

SRAM Autodesk cranks - 1

SRAM Autodesk cranks - 1SRAM radically redesigns cranks with specialist software and 3D printing

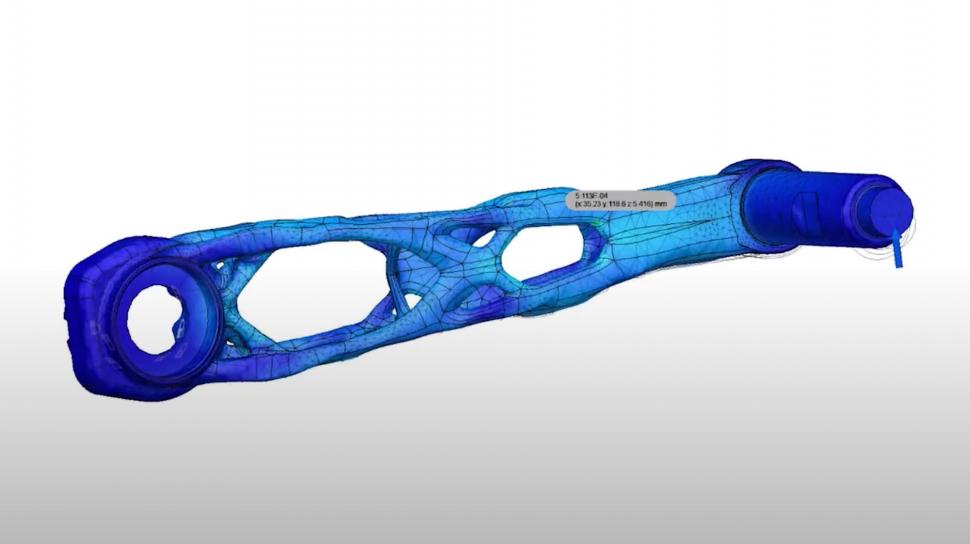

SRAM has worked with Autodesk software, generative design and additive manufacturing, also known as 3D printing, to produce prototype titanium cranks that are said to be twice as strong and 20% lighter than those that use traditional techniques.

Generative design algorithms explore numerous design solutions, working towards defined goals while considering given constraints. Autodesk has posted a video online, reported by Forbes, that explains what is going on here.

“We started this project with Autodesk as a leader in generative design technology so that we could pair that with what we understand about bicycle design, and look at optimising our crank arm designs,” says SRAM’s senior design engineer Will King.

“We chose the crank arm for this generative design project because it's a large structural member.

“From the digital idea to the physical element, additive manufacturing [also known as 3D printing] can help get you there quicker, allows us to bring the idea into physical space to evaluate it, test it, ride it, then go back and decide what elements of the design we want to put into our production drivetrain.

“For SRAM the end goal is to deliver cycling components that inspire the rider and make the bicycle faster and generative design is a tool that is allowing us to not only optimise performance parameters for the rider but also shorten our development time to try new ideas, evaluate them, throw them out or give them more merit and bring them to the prototype phase. Then we're able to deliver those new ideas quicker to the end-user.

“At SRAM we're an innovation company and so as we look to inspire the consumer with our components we want to continue to add innovation and make that riding experience better, and generative design is helping us get to that finish line quicker.”

Obviously, Autodesk is interested in promoting the benefits of using its software, but you get the idea that SRAM is enthusiastically embracing new tech as a means of improving the products it can deliver to consumers.

Autodesk’s Sean Manzanares says, “What we're doing is utilising artificial intelligence as well as super-computing power which allows you to come up with dozens or hundreds of different designs that no human could ever think of, and you're getting those in a fraction of the time.

“We took [SRAM’s] past crank arms as inspiration, and we use our design exploration software called generative design inside of Fusion 360 [software]. You have to bring in new design tools to think differently and do things differently. You're going to use innovation as the key to bring in the new methods of creating and manufacturing your products.”

SRAM has created working prototypes. The lattice/beam structure looks super-cool but also as if it’ll serve as a mud trap. Bear in mind, though, that some form of skin on a production version could easily stop that.

There are, of course, plenty of hollow cranks on the market that are designed to save weight, and many manufacturers mill their cranks to remove unnecessary material, but the SRAM prototypes appear to take this to a whole new level. We don’t have a weight for them.

The video is mountain bike focused. Aerodynamics would be a further consideration in the road world although, again, a skin would presumably neaten things up there.

We’ve approached SRAM for further comment, asking whether we’re likely to see these cranks in the real world any time soon or whether they're unlikely to progress beyond the prototype stage.

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- chrisonabike 59 sec ago

Agreed - if you've had the bike a while you've probably added bits to it / upgraded. In my case that included about 150 quid of cut locks...

- chrisonabike 5 min 57 sec ago

Hmm... I'm sure "more could be done" but there are two parties here. It seems hard to reach people with "council information". Particularly with ...

- mdavidford 30 min 47 sec ago

"Driver fined £100 after stopping to be sick" https://www.bbc.co.uk/news/articles/ce8g13pp0plo

- ktache 54 min 11 sec ago

Not that they would be as technical, or maybe quite as grippy, but does the skate industry provide any solutions?

- wtjs 1 hour 9 min ago

the Metropolitan Police contacted Vikash to inform him that they have created a report for the incident and that the video has been “passed to the...

- Rendel Harris 1 hour 36 min ago

Sorry to be a killjoy but it doesn't amuse me at all, I hope the idiot gets caught and punished. Putting yourself on the same road as pros...

- willpom @GWRaudax 2 hours 11 min ago

Steve Poulton has just published The Cheltenham Flyer - 10th May https://www.audax.uk/event-details/calendar/13235-cheltenham_new_flyer_200

- David9694 2 hours 28 min ago

Chef left with 'car sticking out of house' on crash-hit road...

- HKR 5 hours 22 min ago

It's not 4k though. It's a 4k sensor. But when image stabilization is on, that's chopped down to little over a 1080 image. ...

Add new comment

19 comments

Perhaps SRAM could design cranks that don't require stumping on a meter long breaker bar to remove them?

I remember thinking that indexed shifting was unnecessary, all those years ago, but I realise how wrong I was when I rejoice in using the El Cheapo but fantastic Sora 9 speed as it shifts perfectly. Hollowtech II was also a great advance over square hole cranks, probably more for the integrated crank-axle and outboard bearings than the hollowing out of the cranks- these innovations had already been accepted before I realised they existed, so I was pretty sure they were a good thing before I installed one. Therefore, I don't trust myself to spot a good thing when it's starting out, but I'm going to be surprised if this is one of them: it's a lot of effort for not very much gain for very few people. I'd be keener to try out those funny new sprockets, the Enduo, with half as many teeth

https://road.cc/content/tech-news/new-motion-labs-reinvents-sprocket-increased-efficiency-283111

I'm jolly glad that they are twice as strong because my rubbish conventional cranks are as floppy and weak as a damp Rich Tea and I'm fed up with having to carry spares all the time in case they break mid-ride. I go through dozens of cranks a week due to this problem.

My early Middleburns were flexy as hell and I have gone through a fair few cranks in my time, I think small cracks develop around the holes from impacts, wether these would be immune from this who knows. It can be very painful when a cranks properly goes. One of the hollow Shimano road ones seems prone to disintergration.

SomeA lot of people produce a bit more power than you do.Ouch. Very ouch.

But there is a serious point here. Anyone riding a SRAM red crank is using the same kit as many of the most powerful riders. How many fail? Is it enough to need twice the strength?

Engineering design is about choosing compromises appropriate to the application. Light, strong, cheap etc.

looks like something pulled out of a bonfire

On reflection I'm surprised it has taken so long. The design software for optimal shapes etc. has been around for decades - casting has been able to do that for longer. I'm not sure I would trust 3D printed cranks - perhaps it would be safer to use it to make moulds for more conventional casting.

Casting would required investment casting which in Titanium is no joke. Modern laser sintered titanium is on a par with casting in terms of homogeneity. 3d printing also allows shapes that are near impossible even with casting (short of a something like a lost pla process where the male buck for the investement is 3d printed in the first place).

Pavlo, I was following that nicely until your last sentence (the bit in the brackets) at which point you stopped using the English language as I understand it! Would my summary of that bit "which is difficult and expensive " be about right?

so this is a new application rather than an innovative technology - as a designer, this tech has been gaining traction for a decade but is only really getting to the point where things are really happening. the key relationship is between design and manufacturing - you can only design what you can make , but additive metals means you can do things that are impossible with any other form of manufacturing, this is where this comes in...so once you can make any form, you need the software to show the possibilities beyond our normal parameters. this will also be working with stress /strain and load path diagrams from structural engineering to put material where it is needed. easy to skin or tweek the aesthetics/aero, easy to print any size variation since each item is individually made.

PS exciting!!

Its a big improvement over the silca "knob"

I was about to write that I thought they'd go very well together.

Toothbrushes out.

You could simply heat shrink a plastic cover over the exposed part to keep the mud out.

Better still, you could design it with a revolutionary cover of metal all the way round so no mud could get in!

And charge a pretty penny for it??? good thinking batman!

Better still, you could completely miss the point.

Even better you could miss the joke