- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

9 things they don’t tell you about tubeless tyres

You’ve probably heard lots of good things said about tubeless tyres – better puncture protection, comfort, rolling resistance and so on – but have you heard about the downsides? The tyres can be a pain to fit, sealant makes a mess everywhere and there are huge compatibility issues, as we explain below.

- Buyer's guide to tubeless tyres — all your options in new technology rubber

Tubeless might just be the best thing since the invention of the pneumatic tyre, or it might be a complete waste of time. The history of bicycle product development is littered with as many rubbish products as significant ones, but in our view tubeless tyres are a big step forward (you may beg to differ). Even so, as the technology stands today tubeless has its drawbacks – some of them are pretty well known, others less so.

Here are some of the cons of current tubeless tyre technology.

No more punctures...

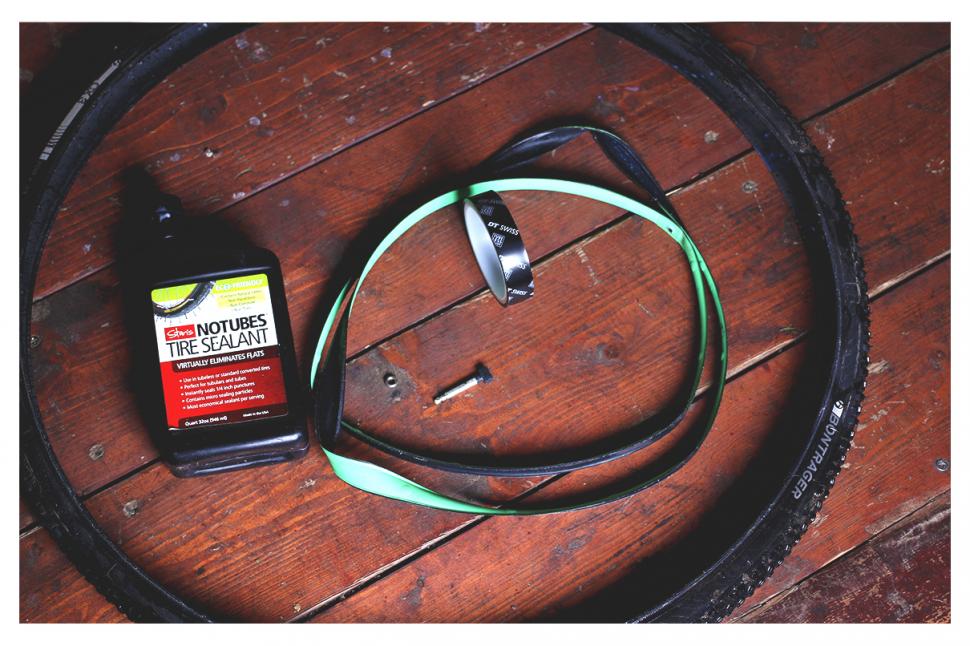

Before we get into the downsides, let’s start with a positive. One of the key benefits of a tubeless tyre setup is a greatly reduced risk of puncturing. The liquid sealant inside is able to seal smaller holes caused by glass, flint or stones and plug the hole because it dries very quickly.

When you witness it happening firsthand and are able to continue riding without needing to replace the inner tube you'll be convinced that this is the future.

...but doesn’t plug all holes

That said, tubeless isn’t invincible and the sealant won’t seal all holes above a certain size, generally about 6mm, because it’s simply overwhelmed by the speed of the air rushing out. This means you might, in rare cases, find yourself with a flat tyre and sealant everywhere. Messy!

For really big holes that the sealant can’t fix, you have two choices, either whack a tube in or use a tubeless repair kit involving an odd rubber anchovy – yep, that's what they're called – which you stuff into the hole to seal the tyre. They’re popular with mountain bikers but yet to be embraced by roadies. You can read a review here. So that's something else you need to buy. The price is creeping up.

You still need to carry a spare tube

Yup, it’s advisable to carry a spare inner tube even though you’ve banished them from your wheels, just in the rare event that the sealant can’t plug a hole.

Installation issues - the tyre just won't fit

This is the biggest problem with current tubeless tyres. Fitting a regular (non-tubless) clincher tyre and inner tube is mostly painless. At worst you might need a few tyre levers, but after that, a small pump will get the tyre inflated onto the rim. It takes about five minutes.

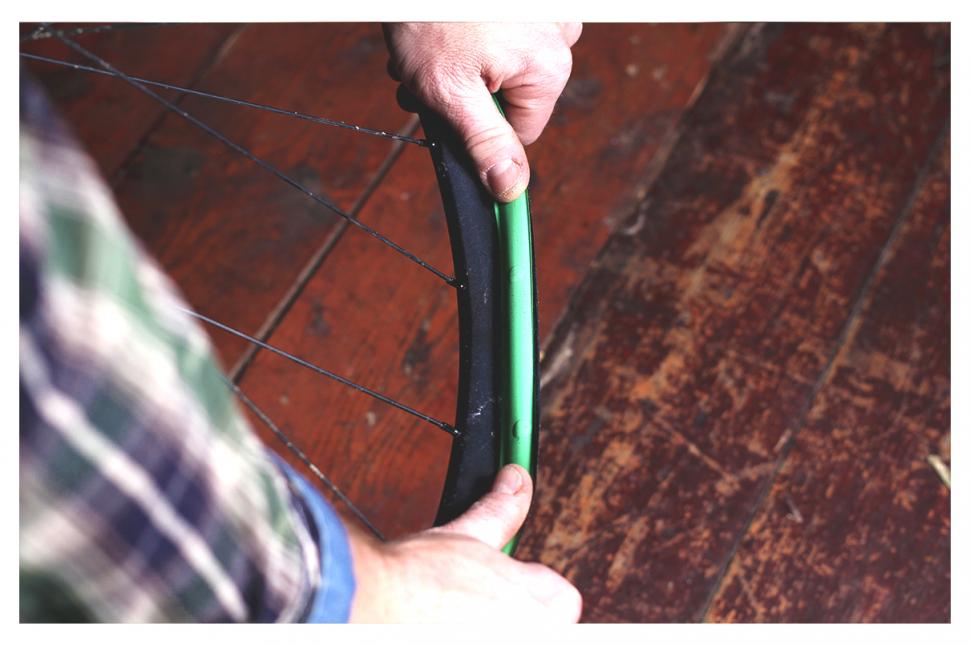

Some tubeless tyres, however, can take much more time to get fitted to the rims and involve much cursing. The problem is due to there being no one standard that all rim and tyre manufacturers adhere to. Also, because you need a very good seal with the tyre bead on the rim, it generally involves a very tight fit... in some cases so tight that you need multiple tyre levers. We've known people to give up, it can be that difficult.

When you've got the tyre onto the rim, it's not all over. Nope, in some cases, you need a tubeless-specific pump, CO2 canister or compressor to deliver the big burst of air needed to pop the tyre up onto the beads.

Much of the problem with tricky tubeless installation comes down to the issue of compatibility between different brand rim and tyres, and a lack of a universal standard. There is wide variation in rim and tyre size and bead stiffness, which affects installation and safety. Keeping the tolerances small is crucial to the success of the system because without an inner tube pushing the bead against the inside of the rim there needs to be a really good fit to ensure the tyre doesn’t come off the rim.

- One step closer to a road tubeless standard? And why this matters to you

The result is that some tyres are a breeze to fit to some rims, with the complete opposite true of a different tyre and rim combination.

This is slowly changing, though, with more brands making their tubeless tyres to ETRTO standards and we have to say that similar issues can affect tubed clinchers. That said, the issue seems to be magnified with tubeless.

There’s a difference between tubeless-ready and tubeless rims

You do need to be a little careful if you’re upgrading to a new wheelset when going tubeless as there is a difference between a tubeless-ready rim and one that is designed for tubeless-only tyres.

The difference can be found at the rim bed and specifically, where the tyre bead sits. Hookless rims (above) are designed for tubeless tyres (although you can still use them with an inner tube up to certain pressures; different brands offer different advice on this), and as the name suggests, they do not feature a hook on the rim.

Tubeless-ready rims, meanwhile, offer you a wider selection of tyres as you can use standard clincher tyres and tubeless-ready tyres. A tubeless-ready rim (above) keeps the hooks that you’d expect to find and they don’t come with the lower max tyre pressures of hookless rims either.

Which one is better? That’s not a debate that we’ll get into today.

It can be messy

All that sealant invites the risk of a mess, and sometimes tubeless can be a messy thing. If you get a puncture while riding, unless you have mudguards you could spray sealant all over your frame, bum and back and anyone riding behind you. I’ve seen this happen and while it’s funny, it’s not nice at all.

When a tubeless installation goes wrong, you can be left with puddles of sealant on the floor or ground of your workshop/kitchen/office. Try explaining why there’s white gunk everywhere to your other half!

Tubeless can be heavier

The extra material needed to make a tubeless tyre, and in some cases, the rim as well with additional rim strips, plus the tubeless valves and necessary sealant, means that even though you’re ditching the inner tube, a tubeless setup can be heavier.

The tyres are generally heavier too. A Continental GP 5000 TL 28mm tyre weighs 340g versus 250g for a regular GP 5000 tyre. Removing the inner tube, however, does save you in the region of 100g but you're adding back 50-60g of sealant which negates some of the weight saved, and those tubeless valves are probably a little heavier too, and there's the rim strip if your wheels need it.

Just don't go expecting tubeless to shed loads of weight from your bike with tubeless, although in some cases it can save a small amount. Plus, if you're carrying two spare tubes just in case, that's your weight saved added back to the bike.

- Buyer's guide to tubeless tyres — all your options in new technology rubber

It can be an expensive upgrade

Wheel manufacturers have been quick to embrace tubeless and a lot of new road and gravel bikes are now being sold with wheels that are tubeless-ready, so you’re halfway there.

If you want to go tubeless, you’re going to have to buy new tyres. Now, unless you need to replace worn-out tyres, then it does mean removing a perfectly good set of tyres and replacing them with new tubeless tyres.

Tubeless tyres are a little bit more expensive than the clincher model and you’ll also need to get yourself tubeless valves, sealant and rim strips if the rim bed isn’t sealed.

If your bike doesn’t currently have tubeless-ready wheels then you’re going to need to buy a new set of hoops too.

One alternative to buying new wheels if yours aren't tubeless-ready (and we're not recommending this) is to go ghetto. In the early days of tubeless, especially in the mountain biking world, it was common to use regular non-tubeless tyres and rims and use rim strips and sealant to achieve a tubeless setup. With the higher pressures involved in a road bike tyre it's probably safer to follow manufacturer guidelines and only use approved tubeless components.

Sealant eventually dries out and needs topping up/replacing

Sealant is the magic ingredient that gives tubeless setups their big advantages over inner tubes, in being able to seal punctures.

The liquid sealant required of a tubeless setup doesn’t stay liquid forever. It’ll eventually dry out. I’ve had many alarming cases with road and mountain bikes when I’ve whipped the tyre off only to find the sealant completely dried out!

Muc-Off claims its sealant lasts up to six months after which you’re going to need to top it up. In most cases, the sealant is going to dry out long before your tyre wears out. Now you can either carry out checks every few months by popping the tyre off the rim, or the easiest option is to just top up the sealant every few months.

It isn’t easy to add sealant

When you do need to add sealant, there isn’t really a foolproof way to do it.

Yes, you can remove the core of most tubeless valves, but over time they love to get themselves gunked up with old sealant – and that can make removing the core a nightmare. Then, once you manage to get it out, most sealant bottles don’t fit the valve properly so you’ll inevitably get some sealant dripping down onto the rim, tyre sidewall and – in the worst cases – down onto the carpet. Our Liam is terrible for this.

Now there are specific syringes available for this job but even those are prone to throwing sealant everywhere. This all means that you probably want to have a rag ready.

Sounds like tubeless is a terrible idea then?

If all that has put you off the idea of trying tubeless, we should end by saying that in our opinion the pros of tubeless tyres outweigh the cons. Getting the tyres on and off can be messy and a general pain but the beauty of tubeless is that it's not something you have to do often. There is hope for tubeless to become much more accessible and easier with the industry finally agreeing on new standard guidelines to maybe all these troubles will be a thing of the past and nothing more than teething problems.

Do you love or hate tubeless? Let's hear your thoughts in the comments section.

David worked on the road.cc tech team from 2012-2020. Previously he was editor of Bikemagic.com and before that staff writer at RCUK. He's a seasoned cyclist of all disciplines, from road to mountain biking, touring to cyclo-cross, he only wishes he had time to ride them all. He's mildly competitive, though he'll never admit it, and is a frequent road racer but is too lazy to do really well. He currently resides in the Cotswolds, and you can now find him over on his own YouTube channel David Arthur - Just Ride Bikes.

Latest Comments

- fenix 4 hours 28 min ago

But it's got PNS on ? Honestly. You just don't get fashion.

- mdavidford 5 hours 19 min ago

Debatable. Rule H3 says you should not cut across cyclists, and that this applies whether they're on a cycle lane, cycle track, or on the road. It...

- LookAhead 5 hours 40 min ago

Spot on, Kask's chin strap is faux leather (contra the review's claim that it's real leather) and excellent, by far the best I've used. It's snug...

- David9694 6 hours 58 min ago

Live: Audi crashes on to its roof in Honiton town centre https://www.devonlive.com/news/devon-news/live-audi-crashes-roof-honiton...

- wtjs 7 hours 13 min ago

There is now a development of uncertain veracity on this Nissan, with a photo somebody has sent me suggesting it's stolen....

- belugabob 7 hours 47 min ago

Yes, it does seem reasonable - but not in the motonormativity world, where people just don't want to admit where the problem lies.

- brooksby 10 hours 11 min ago

But at least they're halfway there...

- hawkinspeter 11 hours 53 min ago

I definitely agree that we could do with better crossings and junctions....

- check12 14 hours 1 min ago

click the unsubscribe link at the bottom of them all, then you won't get any more

- Hirsute 15 hours 20 min ago

A few problems here https://youtu.be/0P0a_n6XgrQ?t=125

Add new comment

126 comments

Like just about everything, when it works it's the best ever.... when it doesn't, it's the stupidest invention ever. So..... my take is thus. I love tubeless on my mountain bike. Works great with lowish pressures, no pinch flats, tires ( all I've tried ) have been easy to install. It's still messy and sticky as hell, you need to have/carry more stuff, but here in Arizona the trails are sharp and rocky, cactus and goat head thorns are everywhere, and for whatever reason(s) it works great overall. My off-road riding is more like bikepacking, I love having a big CamelBack full of liquids and essential gear. For road biking I gave up on it but gave it a good try. I just found it not worth it. Every punture I had were usually from the above mentioned thorns which are tiny little pinholes and sealant ( I tried a couple) would just jet out until it hit maybe 40 psi then it would (sometimes) coagulate. I like my road rides minimal, clean, and quiet..... my trail riding dirty and messy. To each his or her own!

I've been running tubeless (Schwalbe Pro One's) on my road bike for about a year now.

On balance, they're expensive, maintenance heavy & a lot of faff!

The worst thing is that relatively small punctures don't seal at road bike pressures (80psi).

On several occasions I've ended up wasting more time trying to deal with a non sealing puncture than it would take to change an innertube. Then there's the clean up when you get home.

Ive tried several different sealants & added glitter without success. Anchovies don't provide a lasting seal (they pop out).

I've recently bought a Stans 'Dart' tool to plug punctures. £25 for the tool & £20 for 5 patches (£4 each!).

The first fix attempt failed because the puncture in my road tyre wasn't big enough. The second attempt was successful.

I've made the investment in tubeless & I'm going to see how things go with the new Stan's tool.

But I'm seriously considering going back to tubes for my next set of tyres!

Tubeless sound... garbage! Started riding in 2010. In 2013 was riding when a badly oriented drain double tapped both tyres. luckily i did not fall in the incoming car. I had it with sidewall cuts, sudden decompression or tire explosion. I went tubulars, and 50,000 kms and 10 punctures (mostly end of tire life) later I am still here to comment or ride 35-55 km/hr. Staple tubulars have been Veloflex Carbon, aarenberg, Conti Competition and Force/Comp. Vittorias would shred first metres, Michelin would also swiss cheese. But none of these tubulars ever gave me the risk and hazard that the first 10,000 kms that clinchers did. And i was learning to road cycle and was way slower.

The repeat horror stories I hear about tubeless are a cautionary tale that they are a dangerous garbage. People damaging rims during installation? People with decompressed sidewall explosion? Conti 5000TL, the very act of getting on the tighter fits on WEAKENS STRUCTURALLY THE WALL. Sidewall imbalance? People forget the deadly Firestone tire sidewall debacle that killed people until an overhaul got it corrected. However tubeless manufactures not only do not have a common fitting standard, they lack A COMMON SAFETY ONE. Folks, bicyles got faster. Am pricing a custom aero bike, Sl7 dogma F12 or Sarto Lampo, 15k, and yes the new tyre standard e.g. campagnolo WTO tubeless SCARES ME. as an aerospace connected professional I know what risk management is. Or I guarentee to any reader that you CANNOT MANAGE the tubeless risk at 35-70 km/hr. you can use 60-80 psi but 180 lbs with 55C asphalt equals BLOW! these are not michelin Pilot Sport 4 S le Mans tested, but silly garbage. So yes, I do believe that tubeless may save 8 watts (with latex?) vs tubulars, but that One % odd Decompression is an unnaceptable risk. bike gone, injury long lasting...We do not chance it in cars, aeroplanes, why would you do it on yourself? Now, caveat. Recreational relaxed posture riders, 25-30 km/hr have an exponentially less risk of serious issues. Rest of cyclists, speed demons above 33 km/hr, better stick to tubulars for one reason primarily, far far far far far safer tire...

My last tubular puncture occured 5,000 kms riding ago. patched it, sewn it, 20 min... So when tubeless riders find 7-8 sealed punctures esp rear tire, I balk, On hot asphalt the risk is nasty! these synthetic compunds cannot be safely patched!!

people should also not infer conclusions from mbt tubeless - different physics speed tire mass and sidewall. works for mbt, not road and speed and heat. be safe, and pressure the industry to get its act together.

Interesting article. I concur with many of the comments, I switched to tubless back in March after years of riding with only a handful of punctures with tubes. My main gripe with tubeless has been the punctures that appear to have sealed with the sealant, only to start spraying sealant on the next ride. I think this is largely due to the higher pressures on a road bike. If I were to run 80 psi, I can imagine this would be less of an issue, but as a heavier rider (230lbs) I don't feel comfortable running pressures that low.

The 'bacon' tire plugs don't seem to work at all on road tires, as mentioned in the comments, the rubber seems too thin to allow them to work, and I've had no luck with Stans DART.

On top of the hassle and time wasted messing with the tires, I discovered that the sealant had gunked up the bottom bracket cable guide, causing the cables to drag and necessitating a cable change.

I've tried two different sets of tires, Vittoria Cora TLRs and Schwalbe Pro One TLEs and Stans Race and Orange Seal sealants and have had the same issues. I'd patched a hole in the Pro One on the rear of my bike at the moment, which seemed to be holding, but last weekend it started spraying sealant from that hole again, so new tire needed.

I've just ordered new (non-tubeless) tires, I've had it with tubeless.

I don't know if anyone is still reading here other than me. I tried fitting GP5000, which was an exercise in frustration. Even with three hands it did not want to know and it was like wrestling a jellyfish, as the bead went over the rim in once place it was coming off an inch further round. Finally worked out a solution. Use a cable tie around the rim and tyre until it's tight. It stops the bead easing over the rim, still makes the ball of your thumbs ache but 2 minutes to get it on compared to 30 of effing and jeffing.

Also Milkit valves are pretty good. There are rubber flaps under at the valve base, once the pressure drops to about 20psi, you can remove the core with no sealant spray. He king the amount of sealant is cleaning and simple with a syringe kit, forcing the flap open so you draw off the sealant and replace it. Bit easier than advised by Stan's about putting he bloody stuff in before getting the bead over the rim. With GP5000's that is just never going to happen.

Heres the money shot! If you cant pop the beads dry then they definately wont pop full of sealant (Cue big mess!)

So, mount the tyre, remove core, inflate and "pop" the beads. Once its seated, let it down gently and inject sealant through core and pump up with core in.

Worst case scenario give the tyre and rim a good soaking in warm washing up liquid filled water. It always seats.

This has been the key for me to easy installation on road and MTB.

My favourite part about this thread is Dingaling's excel spreadsheets to keep track of his maintenance.... Oh how time flies since I first read it.

Genuinely - each to their own personal choices and experiences, personally my experience with tubeless (Mavic UST) has been absolutely awful. The rolling resistance and comfort have been exeptional - but just the day to day living with the system has left me screaming in frustration. I am done with it.

As per script - most will blame the workman and not the tools - I know my capability, skill set and proven mechanical ability, so that is not the case.

Just fit some Conti TL5000s and it was a forearm exploder. Finally got them on with the help of a gigantic tire lever and gained a giant blister on my thumb from trying to roll tires. I just bought a (new to me) Specialized Tarmac and it had brand new DT Swiss PR1600 alu wheels that were tubeless ready and I have been really wanting to give it a go. I am going to keep an eye on this thread and report back after significant testing!

A couple of days ago you re-posted the disc brake article, and now this one. I can't help but feel you just like watching an argument.

Helmets next?

[Edit - I've just read John's blog!]

Just moved a set of tubeless tyres (Schwalbe pro-ones) from one wheelset to another.

Back tyre seated instantly, added sealant via milkit valves and was done in under 5 mins.

Front tyre would not seat, original wheel was narrower internally and tyre seemed to have adopted that shape. Stuck a tube in, rode it for a week (got one puncture...) then tried again. 5 mins done.

Milkit valves make ongoing maintenance a doddle.

In my experience once you've got the hang of tubeless the benefits hugely outweigh the negatives.

My bike is faster and more comfortable and I spend far less time fixing punctures.

Even in this latest setup with associated hiccups it's only cost me half an hour extra compared to a tubed setup.

I swap my tires occasionally and store my road bike in the sitting room. Tubeless at that pressure with its sealent and mess isn't an option! Also it felt odd being able to shake my bike and hear sealent slosh before I swapped those tires for some tubed ones.

I ran tubeless for about 2 years on my summer road bike. One flint puncture in the Alps that wouldn't seal properly beyond 50psi. Following year, pothole caused double blowout with tyres off rims and some damage. I didn't have 2 tubes so it was a call to the broom wagon. The Mavic tyres were also really hard to take off at home.

Of course, this is anecdotal evidence which has to be averaged with the many who have no problems at all. But inner tubes are no real trouble at all, which lead me to the conclusion this is a solution still looking for a problem to solve. If it ain't broke...

He was on his winter bike with full guards. His bum stayed completely clear of all latex sealant I am glad to report, however, the rear guard which caught all the spray then allowed it all to drip out all over the chain stays and rear caliper/ rotor. Let’s not forget that a big selling point is tubeless on a winter bike which prevents trying to fix punctures in the cold and wet...

As he left the valve in, electing not to fit his spare tube he needed to remove the core to refill with sealant. This needed a tool, which luckily our mate was carrying.

Like I said, horses for courses, if you get numerous punctures then I can see the potential benefit. I’ve had so few that it just doesn’t stack up to being worth it for me. Can’t remember my last puncture on the summer bike. It all depends where you ride and what sort of crap you get on your local roads, so once again horses for courses.

As for rolling resistance, unless you are competing it makes sod all difference. If I get to a junction in front of my mates because of my decreased rolling reactance I will just have to stop and wait. Alternatively I can just ride ever so slightly slower and stay with them, so I get home ever so slightly less tired. Makes no odds to me.

And reduced pressures? I used to ride round on tubs and then 23mm clinchers with 100/110psi, I now ride 25mm tyres with 75/85psi on th summer bike and 28mm 4Seasons with 75/80psi on the winter bike and haven’t needed tubeless to do that, and haven’t suffered any pinch flats doing it either. I freely admit that the reduced pressures are beneficial in terms of comfort, but I’ve proved to myself that I don’t need to go tubeless to achieve that benefit.

PP

I agree. I have Conti GP GT on my commute bike and have had 2 punctures in 6,000km on one pair of tyres!

I also have a disc groupset and tubeless-compatible wheels ready to go on a ( Mason Definition | Fairlight Strael | Kinesis 4S Disc), but having heard numerous disc brakes squealing in the recent rain, am minded to return the groupset and wheels for a refund, then continue to ride my Kinesis T3 with rim brakes and clinchers, which to be fair is still a great bike.

Cheaper and more tried and tested. Also it's the default option for bikes.

No faff but if tubes and tyres work for you, stick with 'em. No one should be telling anyone else what tyres to use - likewise it's pretty pointless telling people what not to use if it's working for them. Not sure why people get quite so het up about it, although it can get a bit irritating being repeatedly told what a pain X, Y or Z is, often by people with little or no experience of things. Use what you like.

I've used wetsuit repair glue which takes 24 hours to set as rubber, but I suspect that it's not ideal for roadside repairs. The "anchovies" that are used for more immediate repairs are made of rubber (I think) and the idea is that they end up bonding to the tyre (if they don't fall out as soon as you inflate because the hole was too big for them).

Just to be clear, you will always suffer from 'deflation' if you've got air in your tyres whether you're using inner tubes or tubeless and regardless of punctures.

What you want to avoid is a 'rapid deflation event'.

Hold on a minute, you have maintenance records!

What kind of human are you? Part man, part spreadsheet?

The trouble with comments like yours is they reinforce positive impressions and bias towards tubeless while ignoring the negative facts so people can balance the pros and cons by themselves.

For myself, I find there's a huge imbalance in terms of cost and time. But I get it, you feel on top of the game by just 'doing' it despite its stupidity.

I'm rather unclear from that what you are warning about and why.

Perhaps you could give a clearer summary.

I'm impressed that you managed to get Schwalbe Pro-Ones to last long enough to transfer between wheels - aren't they made from the same material as moth wings?

(Also a fan of Milkit valves)

I recommend you vacuum your lounge to remove hawthorns, glass, nails and tacks.

My experience too, same tyres and Yksion Pro rims (which, with tubes, are brilliant wheels)

On my MTB I used Stans Rims, Stans tubless kit and Sealer and Schwalbe tubless tyres however, that didn't stop sealant perforating out of the sidewalls and 'burping' on the rim, scrubbing the sealant off the inside of the tyres when swapping them out was almost impossible and took an eternity, I did everything by the book but hated every minute of it.

Sounds like he must have had loads of sealant in there for it be able to drip from mudguards onto disks. Myself, I wouldn't worry about it as the latex should just get abraded away (not an expert, though).

Removing a valve core does usually require a tool. I've got a tiny plastic thingy (came with the MilkIt kit IIRC) that can fit onto the valve body - always available.

Yep. Spreadsheets galore. Only way to know how many kms chains, cassettes and tyres are good for and lots of other useless information.

I'm aware of their 'delicate' reputation but I seem to get pretty good wear from mine.

Probably something to do with the moth-esque power I put through them.

I tried giving up spreadsheets for 40 days. It was excel-lent.

Pages