- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

2022 Ere Research CarbonX - 1

2022 Ere Research CarbonX - 1The ultimate road bike tyre? CarbonX and Ere Research say new material increases speed without compromises

Ere Research says that new CarbonX technology incorporated in its Ere Genus CCX tyre can dramatically improve rolling resistance to increase speed without compromising grip or wear.

Ere Research – whose saddles and tyres we have reviewed on road.cc many times in the past – says that it has been working on the development of a brand new material for high-performance road bike tyres with CarbonX, a spin-off of TU Delft (Delft University of Technology), for the past two years.

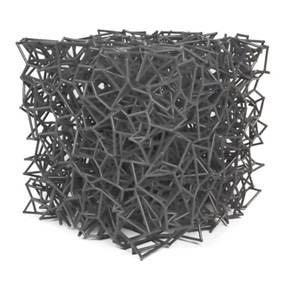

CarbonX, the company, has developed a 3D carbon network structure that’s also named CarbonX.

“With this new material, rubber compounds can be adjusted and specifically tuned to meet the best requirements asked for by professional cyclists,” says Ere Research.

“CarbonX is composed of nano-sized carbon filaments [a nanometre is a billionth of a metre] which are chemically connected to form a three-dimensional micron-sized network. This extraordinary structure makes it possible to combine properties in new ways, the key to unlocking new design possibilities that can deliver both high performance and greater sustainability.

“By using CarbonX, we generate a dramatic improvement in rolling resistance to increase speed without compromising grip or wear. CarbonX is able to make bicycle racing tyres much faster without compromising handling or longevity – keeping the focus on the racer’s safety and chances of success.”

Faster tyres with no downsides? These are big claims. Ere Research says that it was intrigued by the CarbonX material but was initially sceptical that it could work well for high-performance bike tyres because many attempts have previously been made to deliver major gains, with few delivering noticeable results.

Ere Research took its Genus CC tyre, already used in the professional peloton, as the starting point for its CarbonX project.

“In a two-year cycle, you can imagine the number of tyres we tested and the amount of compound we have developed to achieve the perfect compound mix,” says Ere Research’s Piet van der Velde.

“Along with the lab testing and field testing with our pro riders, we have developed the perfect CarbonX rubber for our tyres.”

The result is the new Ere Research Genus CCX.

“For this 320TPI (threads per inch) handmade high-performance tyre, CarbonX is used instead of carbon black particles,” says Ere Research. “By using the new material, Ere and CarbonX achieved a two watt lower rolling resistance (the rolling resistance for the 26mm tubeless/hookless Genus CCX is 9.5 watts, it’s Genus CCR brother is 11.5 watts) and an increase in grip and the anti-puncture value of the tyre.”

Ere Research doesn’t say at what speed these rolling resistance figures were measured, but it does say that puncture resistance is 40% higher than that of comparable competition and is best in class” both on the tread and the casing. It also says that grip levels are up by 66% compared to the comparable competition, also in wet and warm conditions. Ere claims that increasing all of these values at the same time is a breakthrough development that has never been achieved before.

Ere Research has also been working on the casing of the new Genus CCX tyres.

“To make them safer for tubeless and hookless rims, and to keep the weight low and the flexibility performance of these tyres high, [we use the synthetic polymer] Zylon instead of Kevlar as a bead cord in the tyres,” it says.

“Zylon is frequently used in F1 cars as tethers in wishbones that keep the wheels attached to the chassis in case of a crash. It’s a very strong material and perfect for tubeless and hookless tyres.”

Ere Research claims a tyre weight of 220g (26mm version).

The new Genus CCX will be available in 26mm and 28mm widths from summer 2022 for €89, which converts to about £75. A 30mm version will be added later.

ereresearch.com

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- zweiblumen 3 sec ago

The decisive point here is that cyclists already use this route and no enforcement action is taken. I don't see how the residents will be...

- David9694 8 min 1 sec ago

Day 2: "get out of my way" " pay Road tax" "where's your hi viz" "the sun was in my eyes"

- bensynnock 21 min 44 sec ago

'slow traffic flow'....

- Rendel Harris 3 hours 8 min ago

The organisers are Elite Event Management, a for-profit company. Do you not know this or are you just ignoring it?

- check12 8 hours 22 min ago

Surely please get down on your knees, rappers rap about gats not cats and foil isn't made from oil and can hold your all told

- David9694 9 hours 56 min ago

Elderly man sentenced following serious crash in Ringwood...

- Slartibartfast 11 hours 51 min ago

What I find most amazing is that they didn't use this an opportunity to encourage drivers to check their vision and get an eye test. I was waiting...

- the little onion 13 hours 59 min ago

I didn't remove the sound because I didn't think that it mattered - quite clearly the swearing was in reaction to an act of frankly horrid...

- Nigel_2003 14 hours 46 min ago

Know how the limiter screws on your derailleur work and use the right ones to keep chain on a manageable cog at the back and/or chainring at the...

Add new comment

1 comments

CarbonX sounds pretty similar to the Graphene used by Vittoria. Same marketing spiel as well.